FENECON Industrial XL

Fire Protection Information

1. About this document

© FENECON GmbH, 2025

All rights reserved.

Reproduction, even in part, is only permitted with the permission of FENECON GmbH.

2. Version table

| Version | Change | Date | Name |

|---|---|---|---|

V0 |

Initial creation |

31/01/2025 |

Daniel Birkeneder |

V1 |

Revision |

05/02/2025 |

Patrick Melchart |

V2 |

Correction |

13/02/2025 |

Daniel Birkeneder |

V3 |

Revision with optional fire extinguishing system |

21/07/2025 |

Patrick Melchart |

V4 |

Correction |

25/07/2025 |

Daniel Birkeneder |

V4 |

Publication on docs.fenecon.de |

11.2025 |

FENECON PM/MR |

3. Target group

This technical information is intended for planners, installers and operators of Industrial XL electricity storage systems with lithium-ion batteries.

Applicable documents:

-

link:https://docs.fenecon.de/en/industrial/industrial_xl/betriebsanleitung/assembly_and_operating_instructions_Industrial_XL.html [Operating Instructions — Industrial XL]

-

MSDS

4. Expertise

FENECON is characterized by its many years of well-founded expertise in the field of industrial-scale electrical energy storage systems, as evidenced by many references. This illustrates the in-depth experience and trust that customers place in the company’s capabilities. An extensive team of development engineers specializing in battery system technology makes a decisive contribution to the safety and efficiency of the products. Production and product development take place in Germany, which guarantees the highest quality and safety standards. Active participation in various associations also underlines FENECON’s efforts to actively shape cross-industry regulations and safety standards. This involvement enables the company not only to follow safety-related developments, but also to have a significant influence on them. Summarized, these components emphasize FENECON’s commitment to the highest fire safety standards and confirm its role as a pioneer in safety development in the field of energy storage systems.

5. Technologies

In the FENECON Industrial XL electrical energy storage system, FENECON GmbH uses new batteries from the automotive industry based on NMC cells technology, manufactured by CATL, one of the market leaders in battery cell production. The batteries undergo various tests and inspections during development and production by the automotive manufacturers in order to meet the high quality requirements of the German automotive industry. In contrast to vehicle use, the battery in the stationary system is exposed to far lower stress and no extreme temperatures (lower C-rates, more extensive cooling and heating, better cell monitoring), which ensures safe operation and a long service life. The integrated battery management system (BMS) monitors the batteries at cell level in real time. The data is recorded in high resolution and can be evaluated and checked at any time by trained FENECON personnel. Online Monitoring of the FENECON Energy Management System (FEMS) allows the operator to check all current system statuses and error messages to ensure early intervention.

6. Installed fire protection components

In addition to monitoring by the battery management system, a fire alarm system with an optional automatic aerosol fire suppression system is installed in the container. This is used for the early detection of potential fire incidents and - if necessary - the targeted activation of the aerosol release to contain the fire. This fire alarm system comprises the following components:

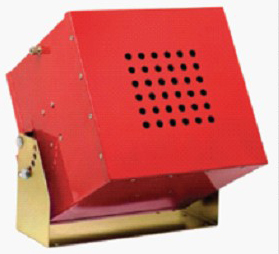

6.1. Integral EvoxX C fire alarm control panel

|

Technical data |

|

|---|---|---|

Operating voltage |

230 V AC ± 15 % |

|

Maximum input power |

max. 160 W |

|

Maximum output power |

max. 113 W |

|

Emergency power supply with rechargeable batteries |

72 h normal operation |

|

Inputs |

two monitored inputs |

|

Outputs |

two monitored outputs for transmission and alarm devices |

|

Output voltage (complies with PELV) |

21.0-27.9 V DC |

|

Additional interfaces |

Connection for Integral X-LINE LAN (100-Mbit-TX) |

|

Activation current of the extinguisher generators |

Between 1.3 and 1.6 A |

|

Temperature range |

-5 °C to +40 °C (VdS-tested) |

|

Ingress Protection |

IP30 |

|

Housing |

Sheet steel |

|

Color |

red, RAL 3000, |

|

Dimensions (W x H x D) |

424 x 445.5 x 144.5 mm |

|

6.2. Multiple sensor detector CMD 533X

Installed in the battery area and switch cabinet area:

|

Technical data |

|

|---|---|---|

Operating voltage |

12-30 V DC |

|

Quiescent current |

0.15 mA |

|

Alarm current |

0.1 mA/1 mA/5 mA |

|

Signal transmission |

Serial, two-wire technology |

|

Short-circuit isolator |

integrated |

|

Temperature range |

+20 °C to +50 °C |

|

Rel. humidity |

10 % to 95 % |

|

Housing |

ABS/PC |

|

Color |

white, (similar to RAL 9003) |

|

Dimensions |

118.8 x 58.1 mm (D x H) |

|

Weight |

125 g |

|

VdS approval |

G212156 |

|

Performance declaration/DoP |

CPR-30-21-001 |

|

7. Optional fire insulation system

The optional fire insulation system also includes the following components:

7.1. Aerosol extinguishing generator Wetrax WX5700

Installed in the control cabinet area (1 piece):

|

Technical data |

|

|---|---|---|

Activation voltage |

min. 1.5 V DC |

|

Activation current |

800 mA for 3-4 sec. |

|

Extinguishing agent |

5700 g |

|

Extinguishing potential |

approx. 49 cbm |

|

Extinguishing time |

15-20 sec. |

|

Range |

8 m |

|

Temperature range |

-50 °C to +95 °C |

|

Humidity |

max. 98 % |

|

Housing |

steel |

|

Protection specification/impact resistance |

IP55/IK10 |

|

Dimensions (L x W x H) |

300 x 300 x 300 mm |

|

Weight |

26,400 g |

|

Certifications |

VdS Germany |

|

Conformities |

EN15276-1, |

|

7.2. Aerosol extinguishing generator Wetrax WX500

Installed in the battery area (3 pieces):

|

Technical data |

|

|---|---|---|

Activation voltage |

min. 1.5 V DC |

|

Activation current |

800 mA for 3-4 sec. |

|

Extinguishing agent |

500 g |

|

Extinguishing potential |

approx. 49 cbm |

|

Extinguishing time |

5-10 sec. |

|

Range |

3 m |

|

Temperature range |

-50 °C to +95 °C |

|

Humidity |

max. 98 % |

|

Housing |

stainless steel |

|

Protection specification/impact resistance |

IP55/IK10 |

|

Dimensions (D x L) |

84 x 295 mm |

|

Weight |

3,340 g |

|

Certifications |

VdS Germany |

|

Conformities |

EN15276-1, |

|

7.3. Manual trigger Hekatron MCP525

|

Technical data |

|

|---|---|---|

DC operating voltage |

19.6 to 30 V DC |

|

Temperature range |

-10 °C to +55 °C |

|

Ingress Protection |

IP54 |

|

Housing |

plastic, ASA |

|

Color |

yellow, RAL 1003 |

|

Dimensions (H x W x D) |

135 x 135 x 36 mm |

|

Weight |

450 g |

|

VdS approval |

G208106 |

|

Performance declaration/DoP |

CPR-30-13-027-de-en |

|

8. Evaluation based on BVES guidelines

For the approval process for the construction of electricity storage systems, the following information is provided regarding the assessment of fire protection as well as the use of extinguishing water and extinguishing water retention for the FENECON Industrial XL battery storage system. The assessment is based on the fire protection scenarios listed for the planning of technical fire protection and extinguishing systems in the "Preventive and defensive fire protection for large-scale lithium-ion storage systems" guidelines published by the Energy Storage Systems Association (BVES; Bundesverband Energiespeicher Systeme e.V.). The BVES guideline distinguishes between four different fire scenarios for the design of fire extinguishing systems for battery energy storage systems.

8.1. Scenario 1

A comprehensive risk assessment was carried out for the energy storage system FENECON Industrial XL in order to identify and reduce potential sources of danger.

In Scenario 1 — Fire within the lithium-ion battery storage system (fire or thermal runaway at cell level), fire protection is ensured by design. As a result, preventive and defensive fire protection measures for this risk scenario can be reduced without the need to add external extinguishing agents; intervention by the fire department for active firefighting is not intended. Instead, the affected battery module should react autonomously and return to a non-critical state by itself after around 30 minutes. Consequently, no measures for retaining extinguishing water are required for Scenario 1.

During this thermal process, high temperatures are generated locally, which — depending on how they spread — can also be transferred to the container shell. A significant increase in temperature on the outer wall is therefore possible. Several pressure relief openings are provided in the container ceiling for the controlled discharge of excess pressure and gases. These allow smoke and gas mixtures to escape in a targeted manner. At the time of discharge, the gases have already cooled down significantly and quickly dilute in the ambient air. Critical contamination of adjacent buildings or plant components through toxicity or corrosion — both horizontally and vertically — is therefore not to be expected.

Fire detection is carried out by a fire detection system consisting of optical smoke detectors and CO detectors, which detect both particles and gas emissions at an early stage. If a fire is detected, a pre-alarm is tripped and the affected electrical systems are put into a safety state. If the fire event is confirmed in accordance with the two-detector dependency - i.e. by two independent detectors - the main alarm is tripped by the system.

Even if the activation of the fire suppression system is not planned in Scenario 1, it remains integrated in the system and serves as a redundant safety measure. In exceptional cases, it can support the automated self-protection behavior of the battery. In this case, when the main alarm is triggered, the aerosol fire suppression system is activated automatically after a defined delay of 30 seconds.

8.2. Scenario 2

In Scenario 2 — a fire affecting a lithium-ion battery energy storage system without defined fire resistance — comprehensive fire protection measures are used. Optical smoke detectors and CO detectors are used for early fire detection, which reliably detect both smoke development and potential gas emissions. In addition, continuous temperature monitoring is carried out directly on the battery cells. If the temperature rises abnormally, the battery contactors are automatically opened to prevent further thermal stress or overloading. The enclosure of the battery system serves as an additional protective measure. It delays the direct impact of the fire on the battery modules and at the same time reduces the thermal energy transferred, slowing down the progression of the fire and minimizing the risk of escalation. If a fire is confirmed, it is first detected by an initial fire detector. This triggers a pre-alarm and initiates an immediate emergency shutdown of the affected electronic components in order to prevent short circuits or overheating as secondary consequences. If the event is verified by a second, independent detector in accordance with the two-detector dependency provided, the main alarm is triggered. With the optional aerosol damping system, the aerosol fire damping system is automatically activated after a defined time delay of 30 seconds in the event of a main alarm. This ensures rapid and targeted containment of the source of the fire inside the container and makes a significant contribution to limiting the damage. The fire suppression system can also be activated manually via an activation switch attached to the outside of the container. In the event of manual activation, the status of the main alarm is immediately switched.

8.3. Scenario 3

In Scenario 3, a fire affects the secondary electronics without classified fire resistance. The same measures apply here as in Scenario 2, including detection by optical smoke detectors and CO detectors as well as emergency shutdown of the affected electronics and, if necessary, activation of the automatic aerosol insulation system. In addition, fire development can be contained by the switch cabinet housing and the electronic enclosures for the FEMS2Battery (F2B) and high-voltage 800 boxes (HV800 box), which delay the spread of the fire and limit damage.

8.4. Scenario 4

In Scenario 4, a fire occurs outside the battery energy storage system container, which heats up the container shell and could potentially spread to the inverters and the air conditioning unit, which are located outside the container. As the air conditioning unit does not use flammable coolants, it does not pose a fire hazard itself, but its function could be impaired by the effects of heat. The container shell serves as a protective barrier to prevent direct fire exposure to the battery modules and to ensure the safety of the system. In addition, an appropriate safety distance from potential sources of fire is recommended in order to minimize the effect of heat on the container shell.

9. Fire protection certificate according to Building Guideline Regulation of Lower Saxony (NBauVorlVO)

9.1. Information according to §15 of the Building Guideline Regulation of Lower Saxony (NBauVorlVO) Section (1)

-

The FENECON Industrial XL energy storage system does not have any fire protection-qualified components such as fire walls or partition walls. In the event of a fire, smoke is discharged through several pressure relief dampers.

-

The container walls and roof are made of non-combustible materials. The container is a fully welded standard model, constructed from hollow profiles and angle profiles. The container frame, container walls and roof are made of S235JR material. The surfaces are powder-coated and have corrosion protection class C4H and are insulated on the inside with a material that is classified as non-combustible in accordance with Euroclass A1 and also has a melting point of over 1000°C.

-

The room-enclosing components do not have a fire resistance class. The cable feed-throughs are non-combustible.

-

The FENECON Industrial XL contains a utilization unit without separate fire or smoke compartments and contains no habitable rooms.

-

The FENECON Industrial XL does not accommodate rooms for people to stay in and does not provide permanently occupied workstations.

-

In the event of a thermal runaway of battery cells due to an internal defect in a battery module, the provision of extinguishing water is not necessary, as explained in the section Evaluation based on BVES guidelines. For other fire cases, a supply of extinguishing water could be ensured by hydrants on site if necessary.

9.2. Information according to §15 of the Building Guideline Regulation of Lower Saxony (NBauVorlVO) Section (2)

-

Details of the use of the FENECON Industrial XL energy storage container.

-

Length of stay of persons in the container:

-

Permanent: none (automatic operation of the system)

-

Short-term for inspection/maintenance/commissioning purposes on the container: approx. 4 to 5 hours

-

In general, the container does not need to be fully entered for inspection/maintenance/commissioning purposes

-

-

Group of persons: Instructed operating personnel of the operator, maintenance personnel trained by FENECON, qualified electricians

-

Explosion hazards: none. Increased fire hazards: none.

Large-scale smoke release from the battery modules is possible, but not probable.

The flammability of gases from the evaporating electrolyte escaping from the battery modules in the event of a fault is not assured. -

Hazardous substances: no open hazardous substances

Substances classified according to the CLP Regulation within the battery energy storage systems (see Applicable Document MSDS) are not classified as flammable and are located in thermally sealed battery cells

-

-

The FENECON Industrial XL has no habitable rooms and offers no permanent workstations. The openings to the battery rooms open directly to the outside. These openings are not designed as escape routes and therefore have no specific markings or safety lighting.

-

Technical systems for fire protection:

FENECON offers the installation of a fire alarm system with remote monitoring and early fire detection ex works. This opens the contactors of the batteries in the event of an alarm. If the fire detection system triggers, the electrical energy storage system’s emergency off is tripped. The system has a UPS function so that it remains active even if the power supply fails. The fire detection system provides information about the alarm and fault status. The statuses are transferred to the FEMS and are then displayed in the Online Monitoring. An optional connection to the customer’s own FACP is also possible.-

Automatic temperature monitoring directly at the cells, which opens the contactors of the battery strings if an abnormal temperature rise is detected.

-

Cable entries for ring cable are provided in the energy storage system connection area

-

Interfaces for an external emergency stop connection are available

-

-

There is no emergency safety power supply. However, a buffer module ensures proper shutdown in the event of power failure.

-

For information on the need for extinguishing water and its retention in the event of a fire affecting electricity storage systems, please refer to the section Evaluation based on BVES guidelines. For fire incidents involving other areas such as power electronics (e.g. inverters), no information is available on the extinguishing water required. Due to the nature of the materials used, no contamination of the extinguishing water is to be expected, which is why measures to retain the extinguishing water are not required.

-

The operator is responsible for measures to prevent fires, fight them and rescue people and animals, including the preparation of a fire fighting plan, the appointment of fire safety officers and auxiliary personnel for their own use.

10. Concluding remarks and further recommendations

FENECON GmbH recommends the implementation of these fire protection recommendations and regular maintenance and inspections to ensure the safe operation of the FENECON Industrial XL. In addition, FENECON recommends early involvement and open communication with the local fire departments in order to plan and define appropriate measures. FENECON is in constant contact with fire safety experts and regularly attends safety-specific conferences. Due to new findings, technical or regulatory changes, parts of this document may change or be further specified at any time.