Installation and Configuration Manual FEMS-Package 3-Phase Sensor 65 A (KDK 4PU)

1. Introduction

1.1. Legal provisions

Unless otherwise stated, the information contained in these documents is the property of FENECON GmbH. Publication, in whole or in part, requires the written consent of FENECON GmbH.

These instructions do not claim to be complete or correct. It merely serves as an abridged version of the original instructions from KDK Dornscheidt.

Subject to changes and printing errors!

1.2. Qualification of the installer

A qualified installer is a person who has the following experience and training:

-

Setting up, switching on, switching off, disconnecting, earthing, short-circuiting and repairing circuits and devices

-

Standard maintenance and use of protective devices in accordance with current safety standards

-

First aid/emergency care

-

Current knowledge of local regulations, standards and guidelines

2. Product description

2.1. Scope of delivery

After you have received the delivery, check that all components have been included. Inspect the scope of delivery for damage. If anything is missing or damaged, please contact the supplier immediately. The following components are included in the delivery:

-

KDK Dornscheidt 4PU

-

Installation and configuration instructions for FEMS Package 3-phase sensor 65 A (KDK 4PU)

-

Installation instructions for KDK Dornscheidt 4PU (Online, available in German: https://www.kdk-dornscheidt.de/wp-content/uploads/2021/08/KDK-Bedienungsanleitung_420565PRO20-U_4PU_052021V1.00.pdf)

2.2. Prerequisites

The following is required for using the 3-phase sensor:

-

FENECON Energy Management System (FEMS)

FEMS is being developed as an open source project under the name "OpenEMS" together with many other companies and institutes in the "OpenEMS Assocation e.V.". More information:

FEMS App: https://www.fenecon.com/fems-apps/

OpenEMS: https://www.openems.io

FEMS is a product component of the integrated FENECON power storage systems and other product combinations of battery inverters and batteries. You can find more information about this at https://fenecon.de/.

2.3. Model overview

The KDK meter is a modular active and reactive energy meter that can count and display the energy consumed. It is designed for three-phase grids and enables direct connection up to 65 A. The meter is equipped with a MODBUS communication bus.

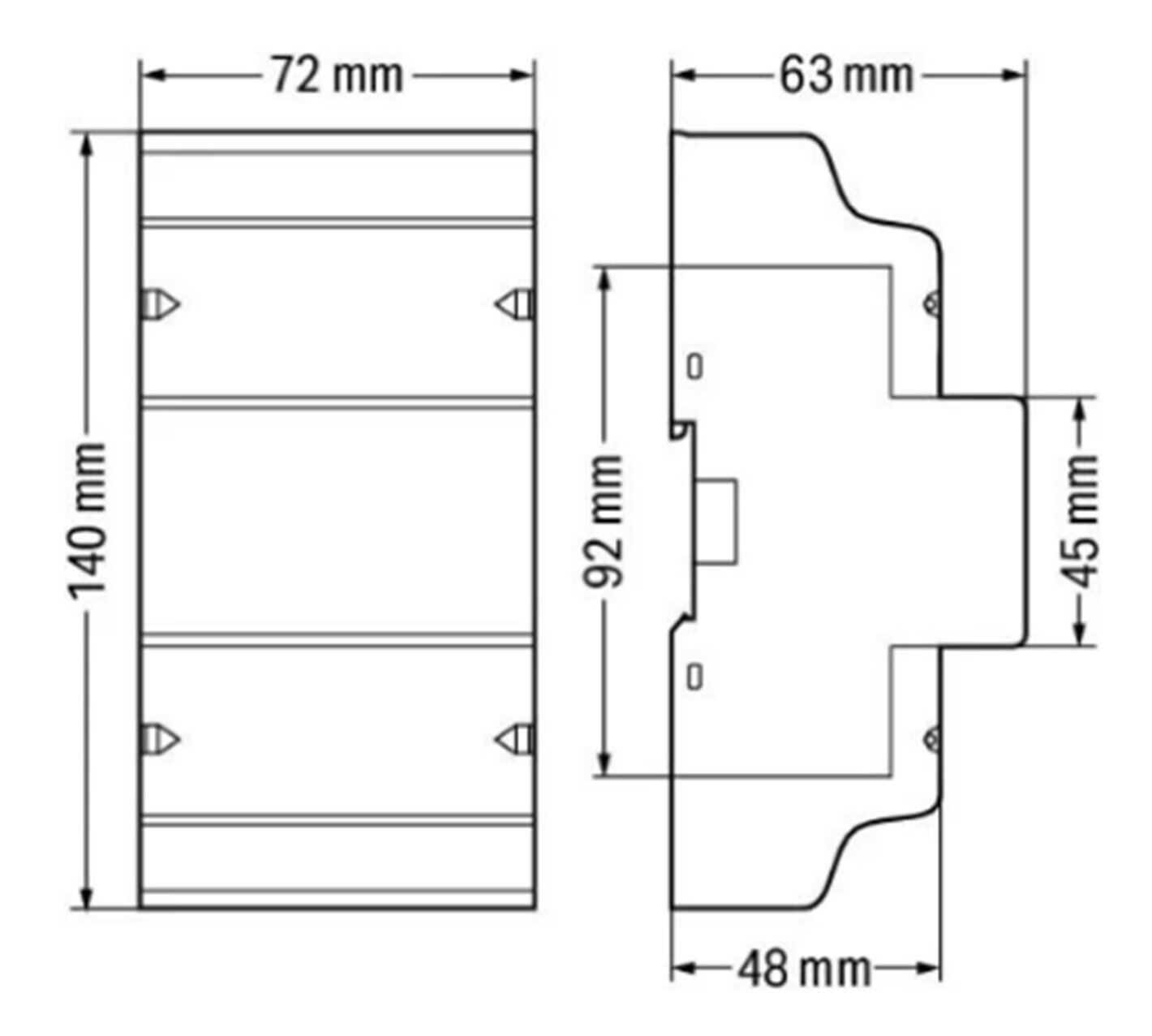

Height without cover |

95 mm |

Height w. cover |

140 mm |

Width |

72 mm |

Depth |

63 mm |

Weight (net) |

0.34 kg |

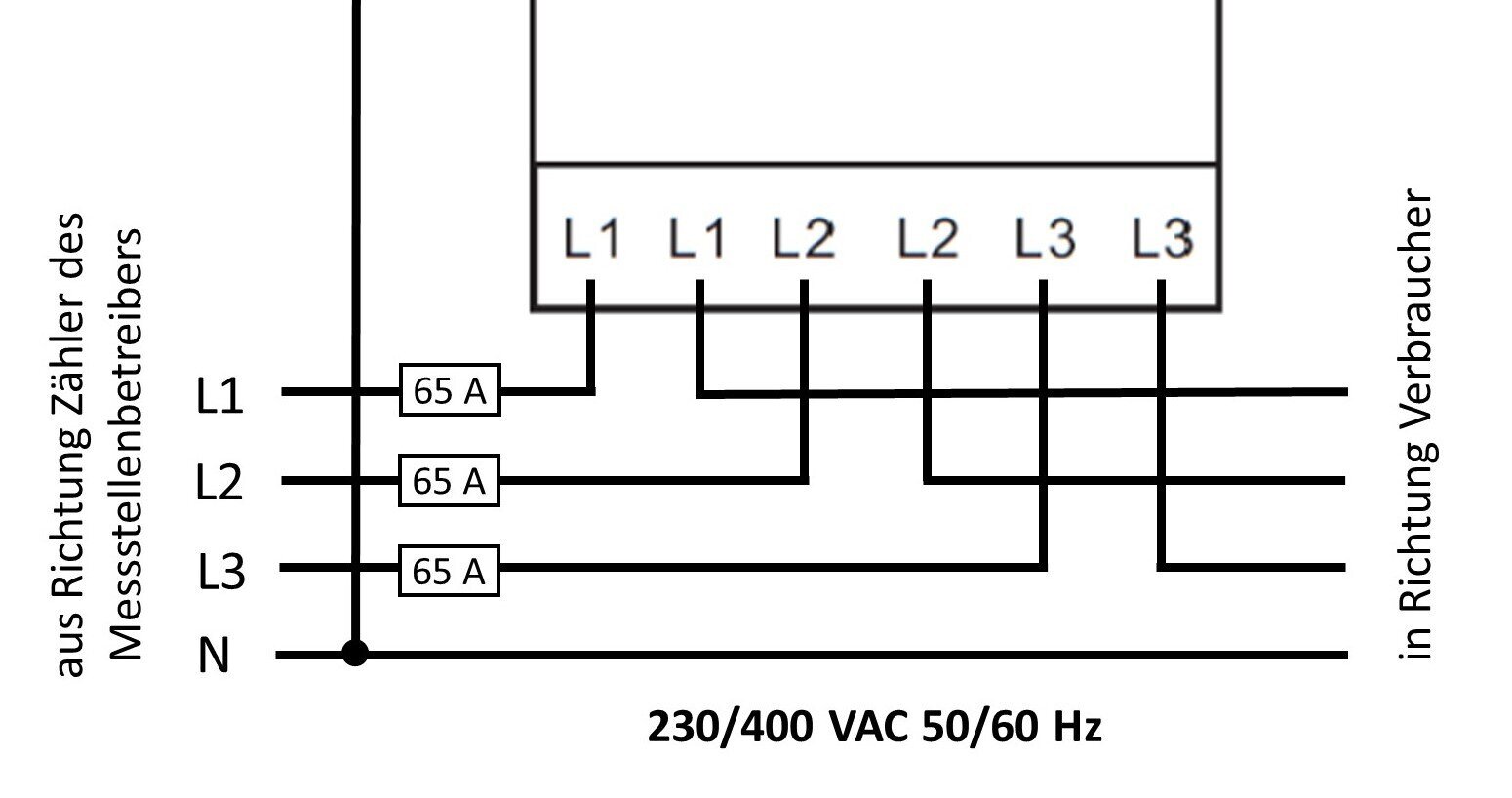

3. Connection

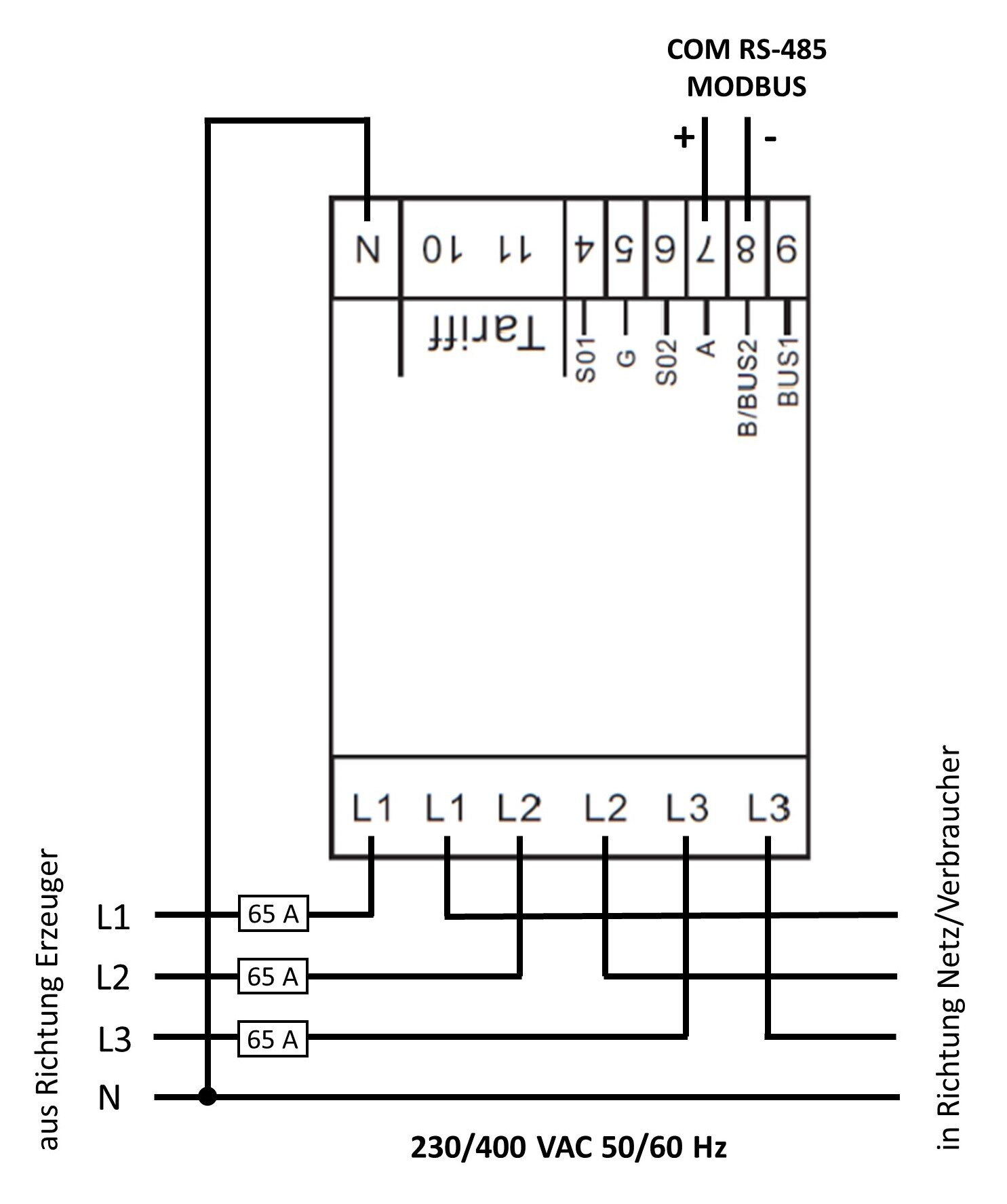

The meter is electrically connected through the 3 phases and the neutral conductor in accordance with the original instructions. The meter has an input and output for connecting the phases. If these are connected incorrectly, the meter may later output a negative value in Online Monitoring.

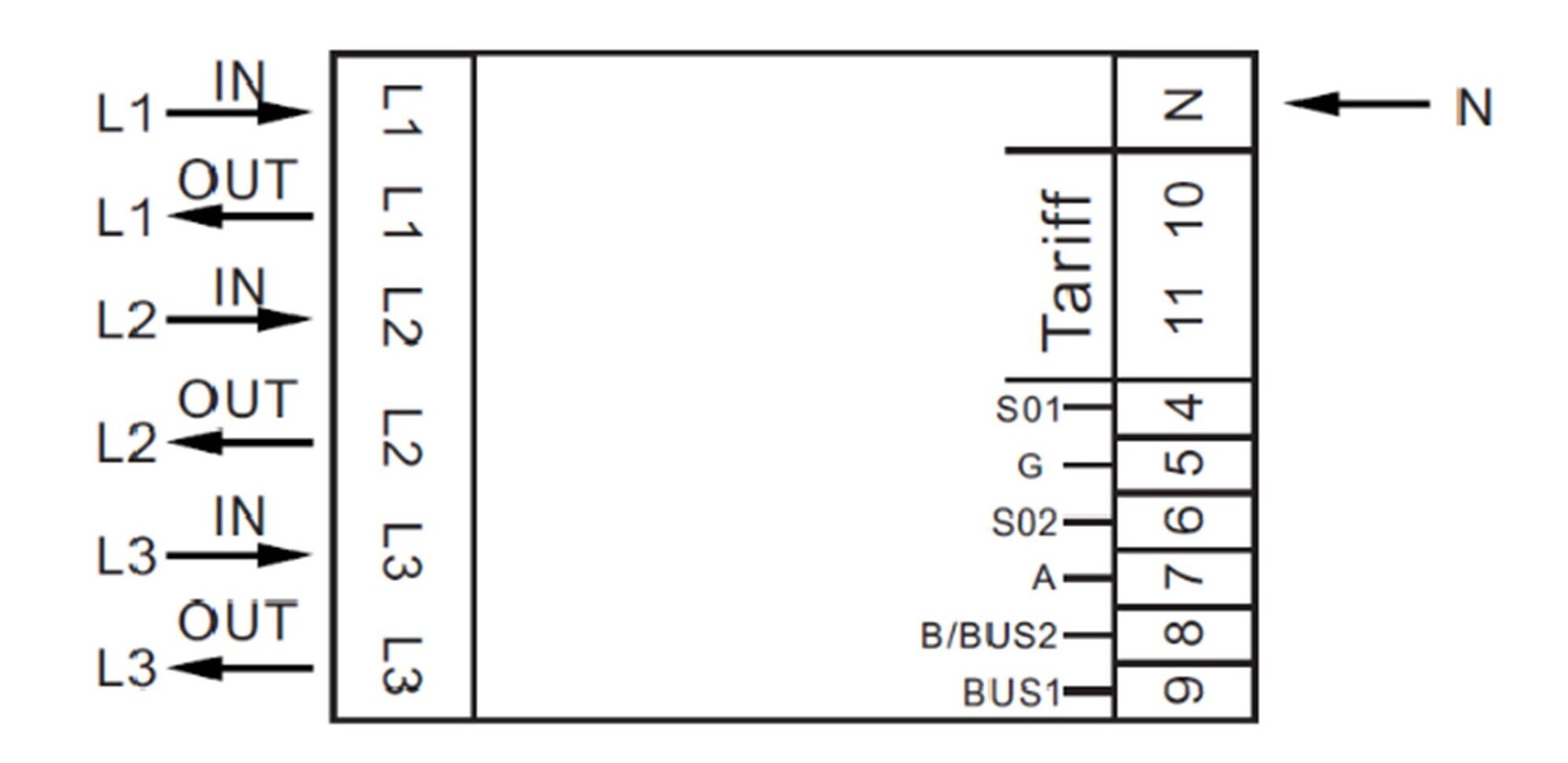

3.1. Terminal designation

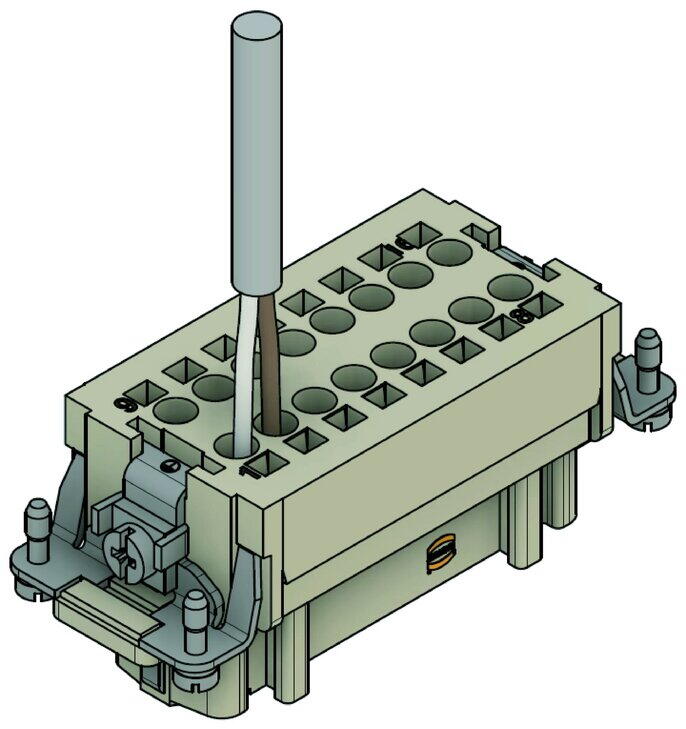

The push-in technique can be used for solid conductors, fine-stranded conductors and fine-stranded conductors with wire ferrule. For fine-stranded conductors, the levers must be opened for connection.

Cross-section of the connection terminals:

WAGO Series 2616 — Main terminal blocks:

- Single-wire conductors

-

0.75 … 16 mm2 / 18 … 4 AWG

- Fine-stranded conductors

-

0.75 … 25 mm2 / 18 … 4 AWG

- Fine-stranded conductors with wire ferrule and plastic collar

-

0.75 … 16 mm2

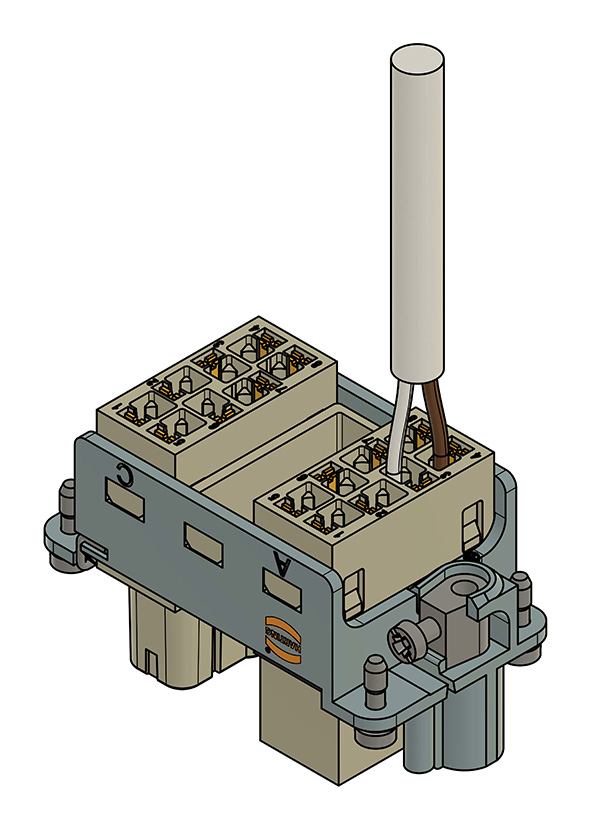

WAGO Series 2604 — Additional terminal blocks:

- Single-wire conductors

-

0.2 … 4 mm2 / 24 … 12 AWG

- Fine-stranded conductors

-

0.2 … 4 mm2 / 24 … 12 AWG

- Fine-stranded conductors with wire ferrule and plastic collar

-

0.25 … 2.5 mm2

4PU — 3P4W |

|

|

IN L1: Input L1 — OUT L1: Output L1 |

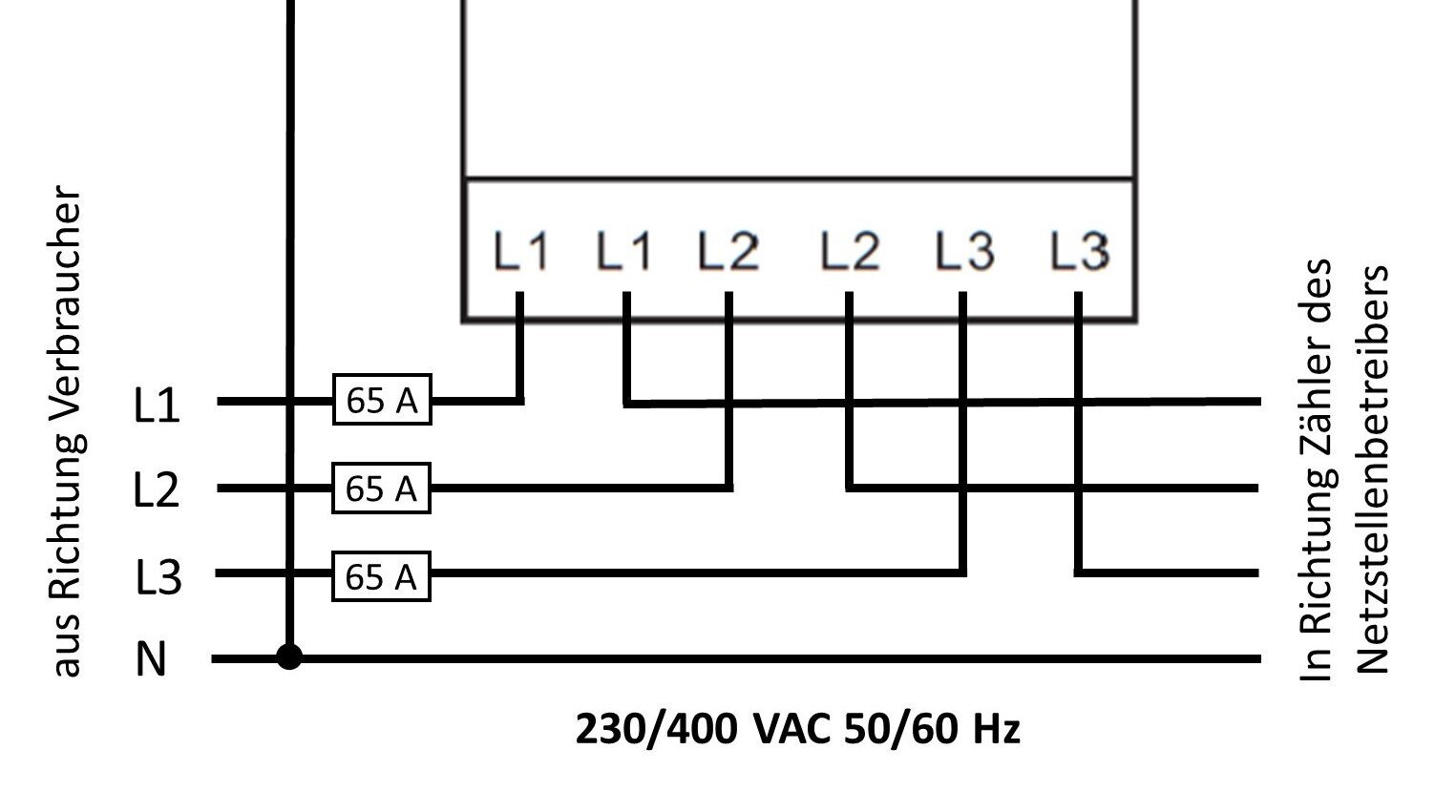

3.2. Connection to a generator

The meter must be connected to the generator (inverter) as shown below:

4. Communication

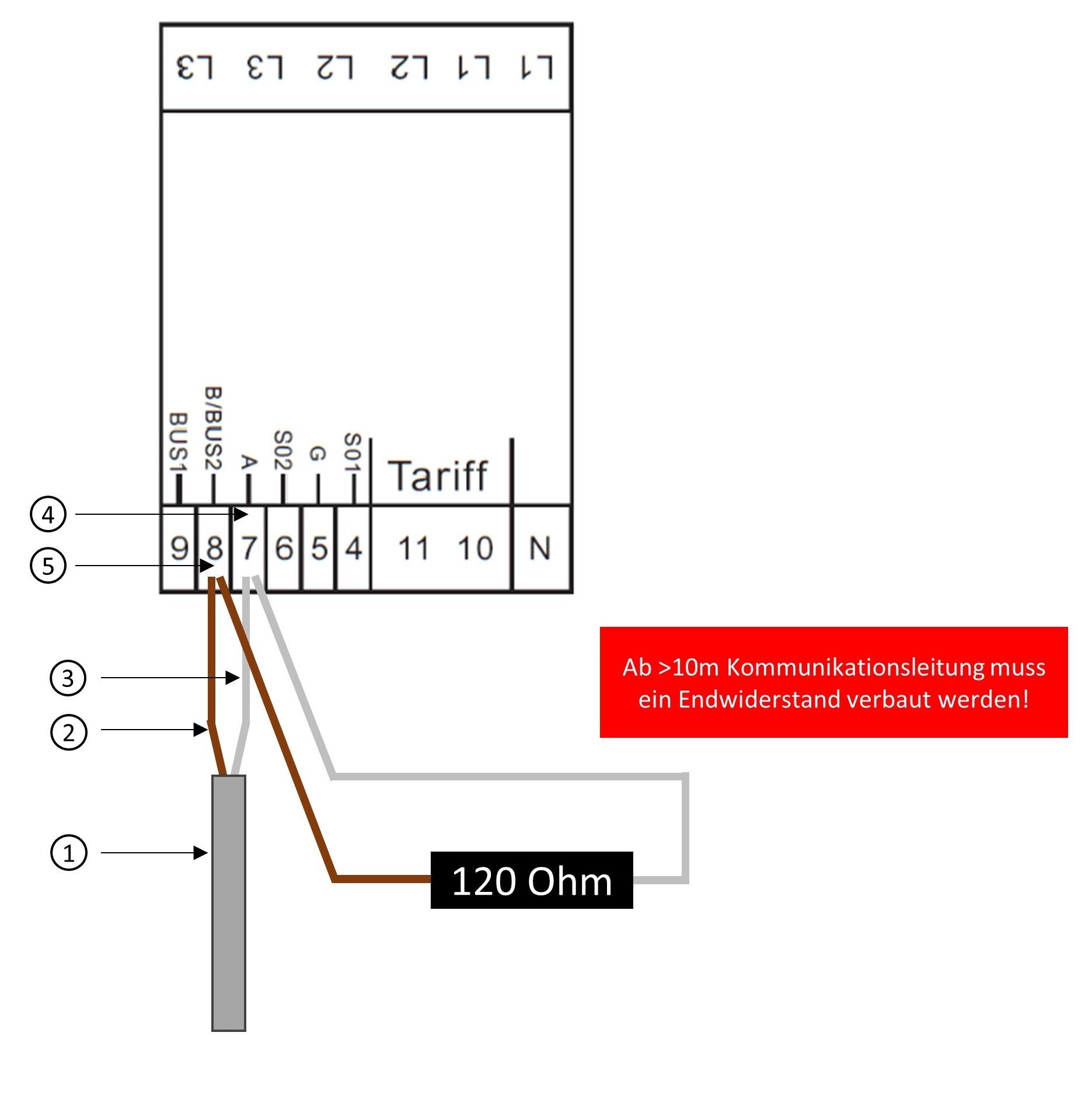

The Modbus communication available with the 4PU takes place via a serial RS485 interface (2- or 3-wire), which enables the device to be operated from FEMS. In the standard configuration, 32 devices can be connected to a PC or a controller over a distance of 1,200 meters via an RS485 interface.

A twisted pair cable is recommended to protect against magnetic fields.

-

COM-RS485 connection from FEMS direction

-

Data conductor Positive (+) (A conductor)

-

Data conductor Negative (-) (B conductor)

-

Minus (-) contact

-

Plus (+) Contact

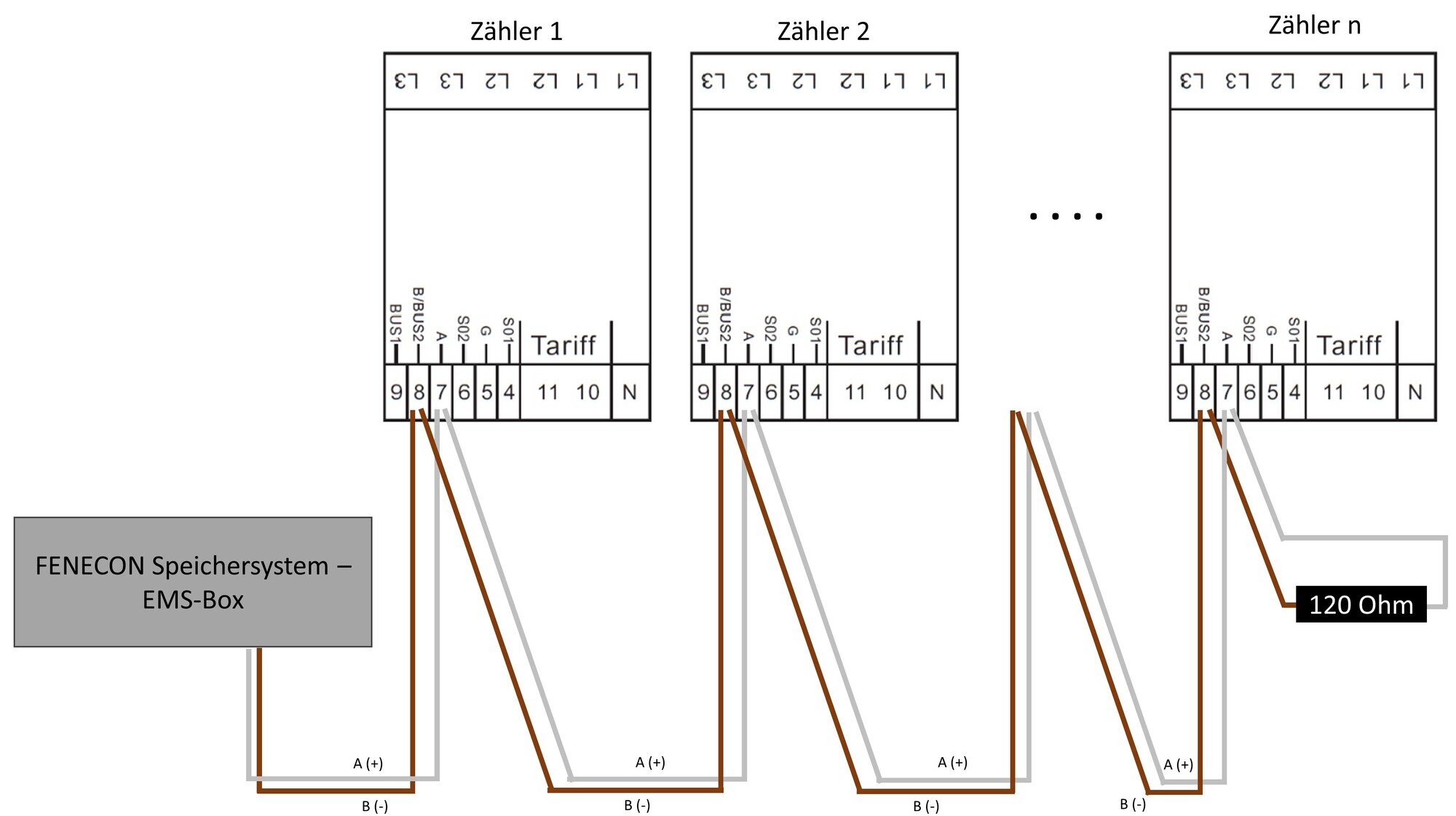

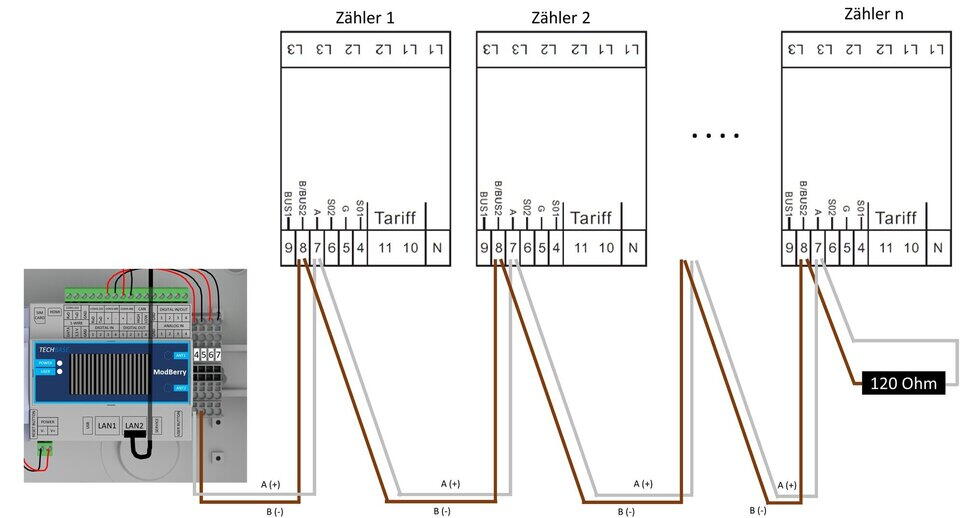

To connect several meters in series, the RS485 connection must be looped through, as shown in the figure below.

Note the connection of the terminating resistor (120 Ω/0.25 W)!

|

If the supplied RS485 cable is not long enough, we recommend using a LiYCY with a cross-section of 0.5 mm2. This is suitable for max. 500 m. In general, the manufacturer’s specifications and recommendations must be observed. |

4.1. Connection — Meter of the FENECON Commercial 30 and 50

In our FENECON Commercial 30 and FENECON Commercial 50 storage systems, the meter is connected to terminals 4 and 5 in the FEMS connection box.

4.2. Connection — Meter on FENECON Home 10

In our electrical energy storage system FENECON Home 10, the meter is connected to pins 1 and 2 of the 16-pin connector on the EMS box.

This can also be found in the instructions for the electrical energy storage system in chapter 8.5 — Additional AC meter.

|

1. Instead of connecting the communication line of the inverter directly to pin 1/2, as described in chapter 6.3.8 (of the assembly and service instructions for FENECON Home 10 and FENECON Home 20 & 30), the communication line to the meter must be connected to pin 1/2. |

|

3. The connection to the inverter is then established from the meter. This means that two cores must be connected to one connection on the meter. |

|

from the battery tower |

white to 7 |

brown to 8 |

|

to the inverter |

white to 7 |

orange to 8 |

|

4.3. Connection — Meter at FENECON Home 20 & 30

In our electrical energy storage system FENECON Home 20 & 30, the meter is connected to pin 3/4 of the 16-pin A-connector on the EMS box.

This can also be found in the instructions for the electrical energy storage system in chapter 10.5 — Additional AC meter

|

1. Connect the cores on the Harting plug (16-pin — A) to pin 3/4 |

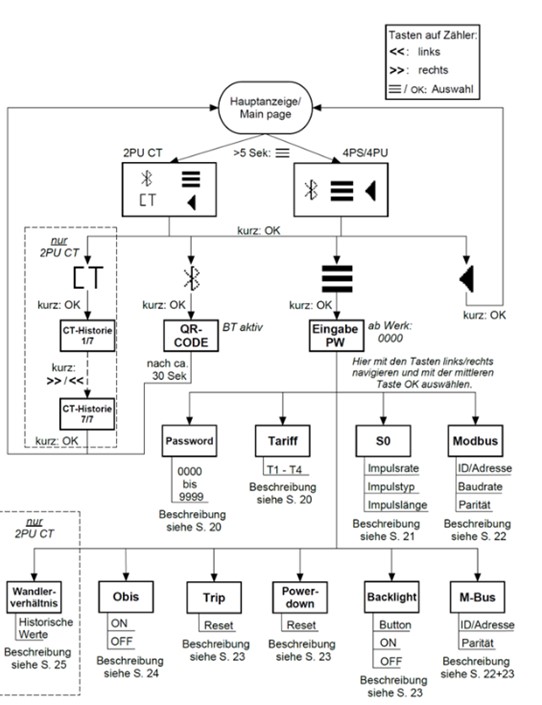

5. Overview — Operating elements

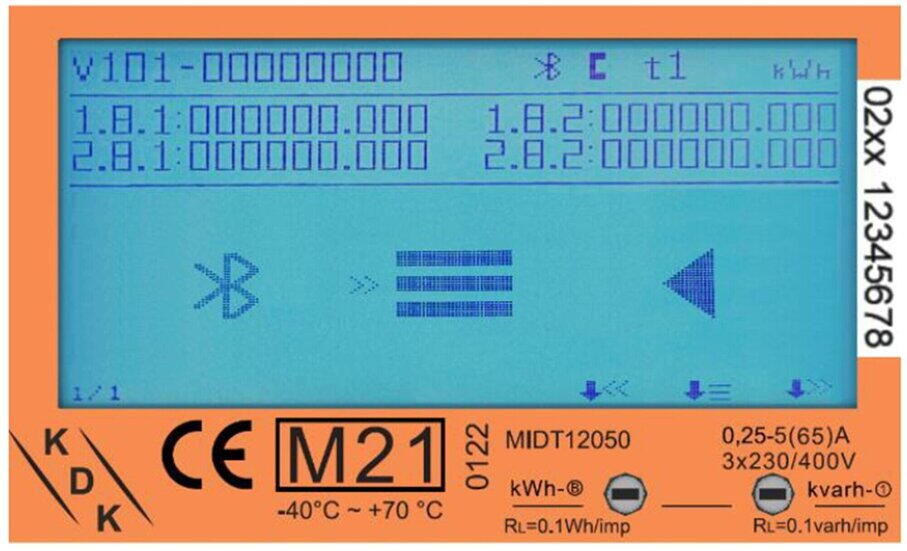

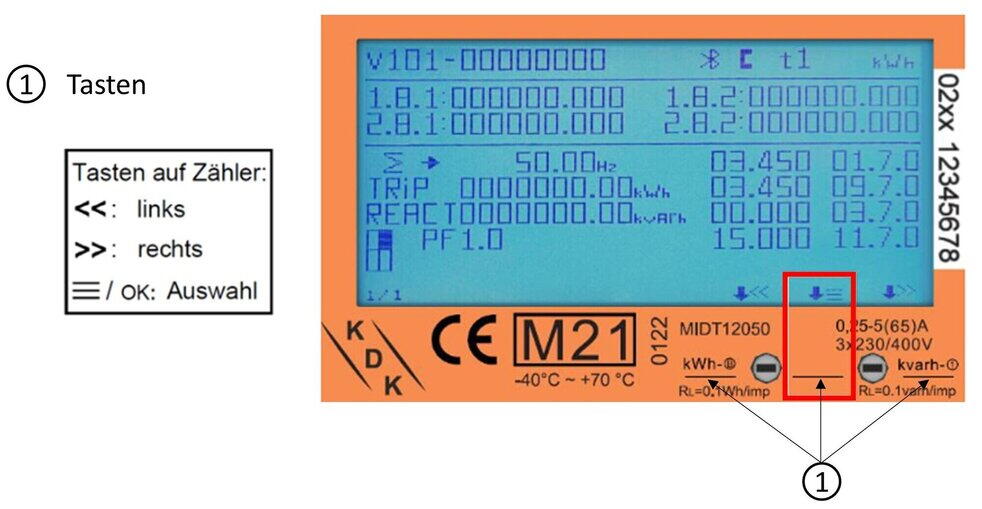

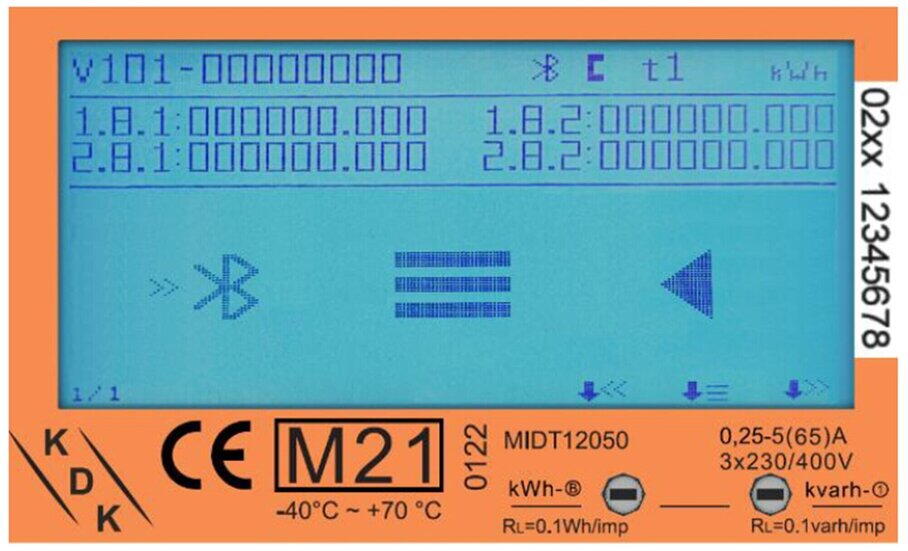

There are three push-buttons on the front of the meter in the bottom right-hand corner, marked with a line. To access the menu, press and hold the middle button for ≥ 3 seconds.

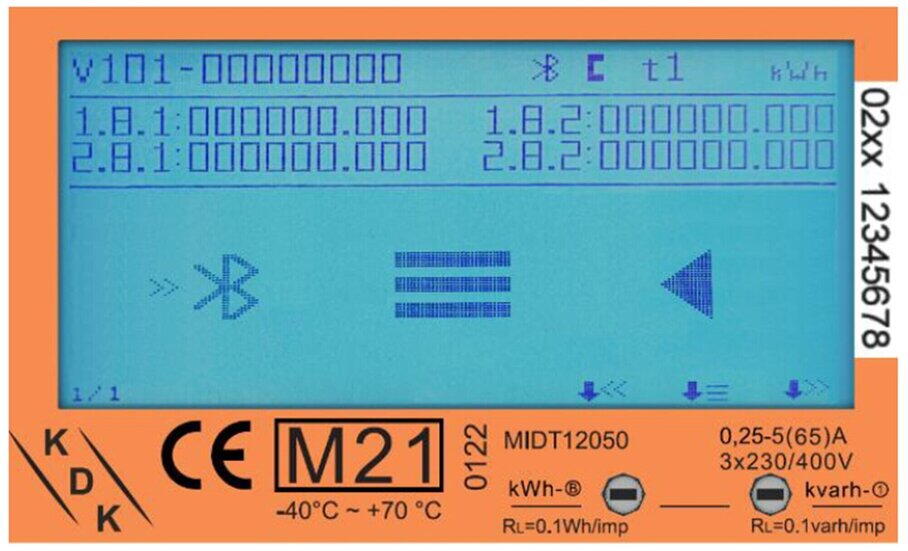

The following display appears:

Here you have the option of activating the meter’s Bluetooth, on the far left in the picture. The symbol in the middle, three dashes, takes you to the actual menu where you can make adjustments to the meter settings. The arrow to the left, on the right in the picture, takes you back to the measured values.

6. Adjust configuration via buttons on the meter

6.1. Configuration parameters

The following configuration settings must be used for use with FEMS:

| RS485 Modbus address grid connection point |

005 |

| RS485 Modbus address PV generation |

006 |

| RS485 Modbus address — other generators/consumers |

007… 246 |

| Baud rate for communication |

9600 |

| Parity |

None |

The symbol in the display, with three dashes, takes you to the actual menu where you can make adjustments to the counter settings. The arrow to the left, on the right in the picture, takes you back to the measured values.

|

|

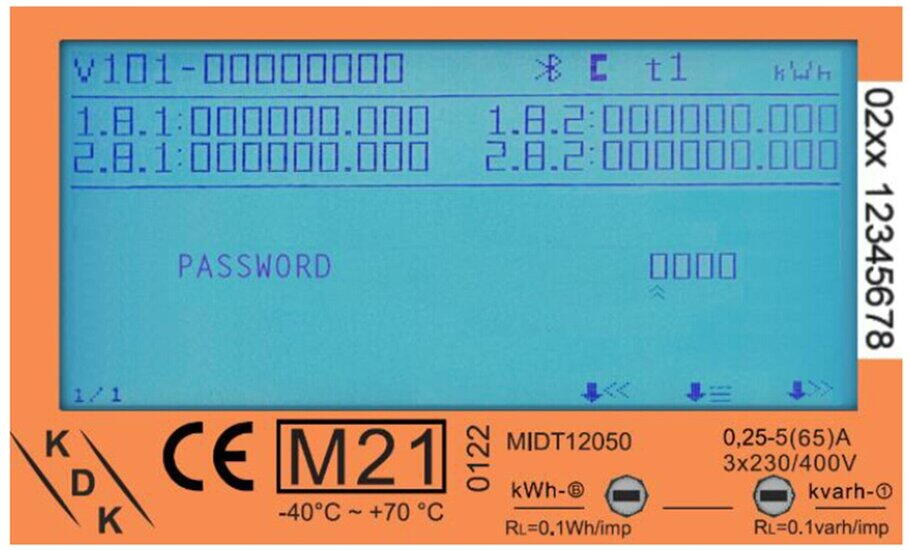

6.2. Password entry

The settings can be made using the sensitive push-buttons on the front of the meter. Use the left and right buttons to scroll through the options. Confirm the setting with the middle button. Select the menu symbol (3 horizontal lines) to access the settings menu:

To access the settings menu, enter the 4-digit password (factory set to 0000). Confirm each digit (0-9) by pressing the middle button:

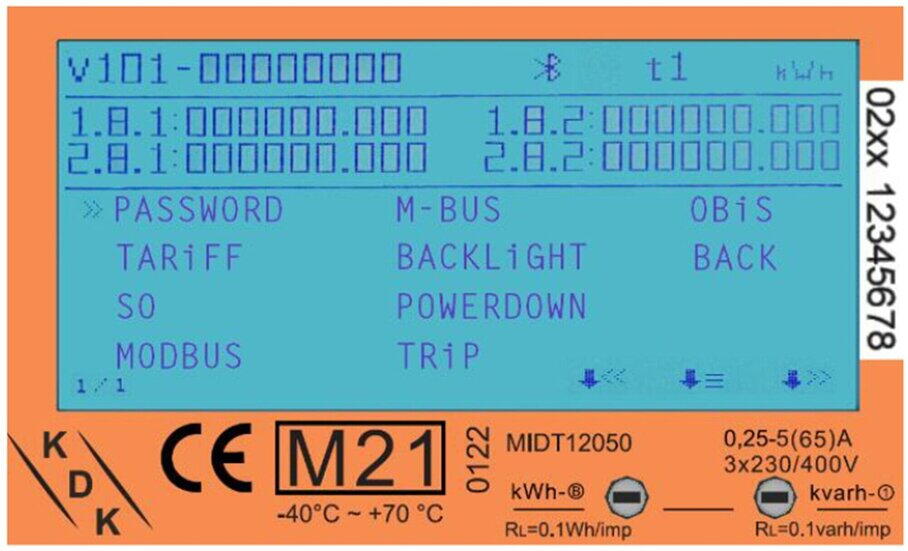

Once the password has been entered correctly, the settings menu appears:

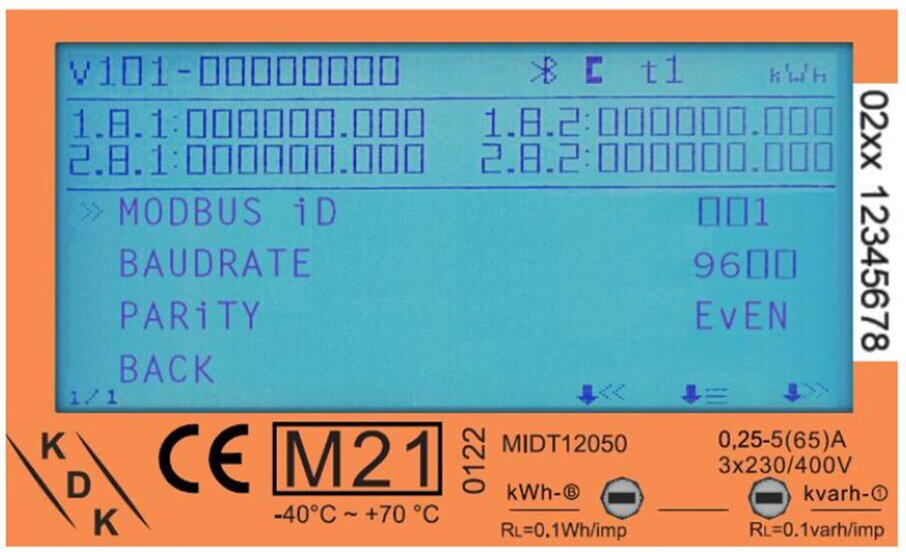

6.3. Input — RS485 Modbus address

To do this, use the sensitive touch buttons to go to the settings menu and select Modbus. Then navigate to Modbus ID and press the middle push-button; you can now use the right and left push-buttons to lock the values. When the desired Modbus address is displayed, press the middle push-button to confirm it.

The factory-set Modbus address is "001". The following addresses are required for communication.

- RS485 Modbus address grid connection point

-

005

- RS485 Modbus address PV generation

-

006

- RS485 Modbus address — other generators/consumers

-

007… 246

|

|

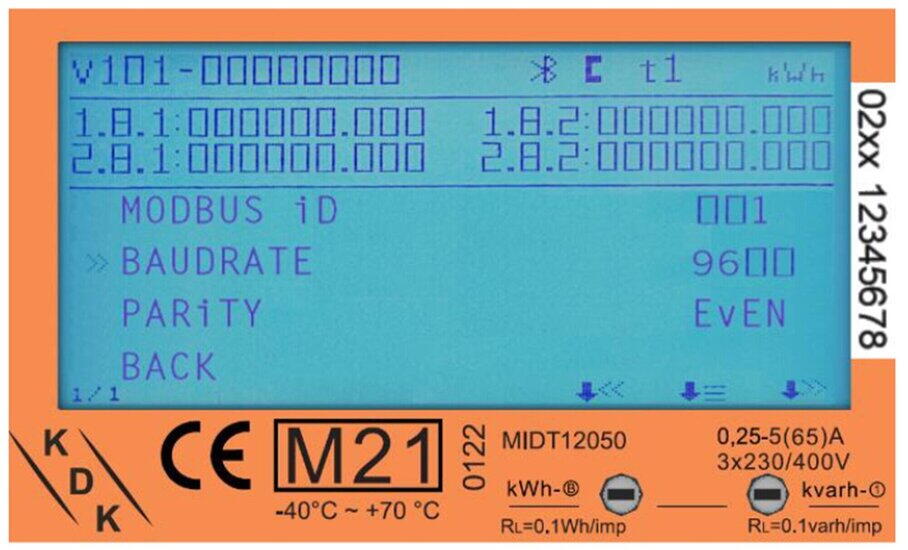

6.4. Input — Communication speed (baud rate)

To do this, use the sensitive touch buttons to go to the settings menu and select Modbus. Then navigate to Baud rate and press the middle push-button; you can now lock the values using the right and left push-buttons. When the desired baud rate is displayed, press the middle push-button to confirm it.

The Modbus® baud rate set at the factory is "9600 Bd". Please check the baud rate.

- Baud rate for communication

-

9600

|

|

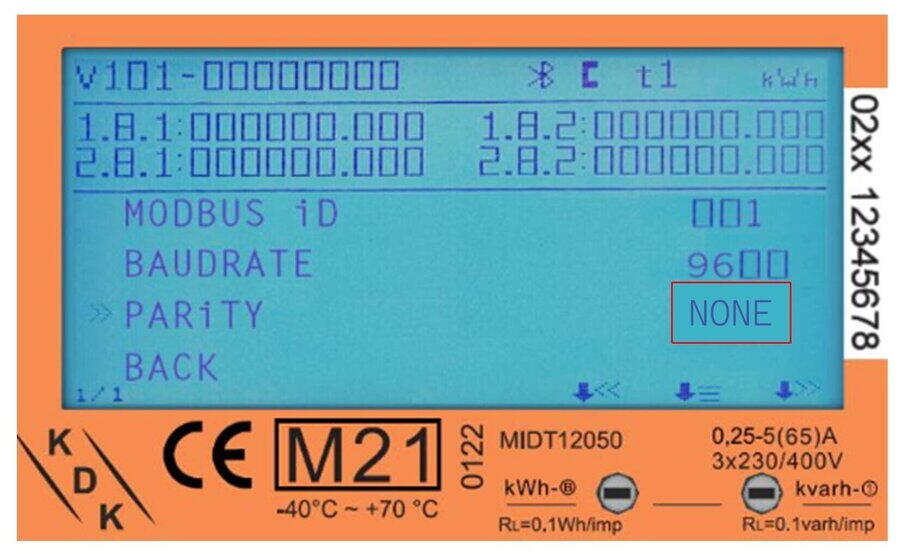

6.5. Input — Communication parity

To do this, use the sensitive touch buttons to go to the settings menu and select Modbus. Then navigate to Parity and press the middle button; you can now use the right and left buttons to adjust the setting. When the desired parity is displayed, press the middle button to confirm it.

|

The factory-set parity is EVEN. This must be changed to NONE. |

|

|

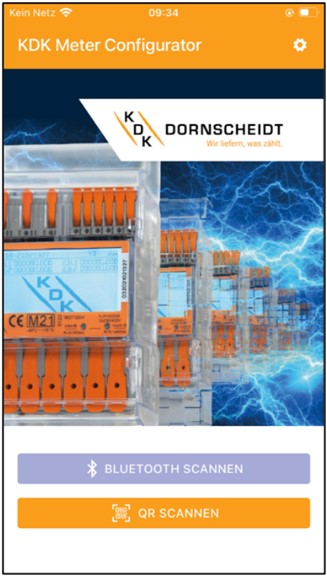

7. Bluetooth smartphone app

All Push-in-CAGE CLAMP® meters can be read and configured via Bluetooth®. The standard used is BLE 4.2. You can download the smartphone app for Android and IOS free of charge from the respective stores. The smartphone app can be found under the name "KDK Meter Configurator".

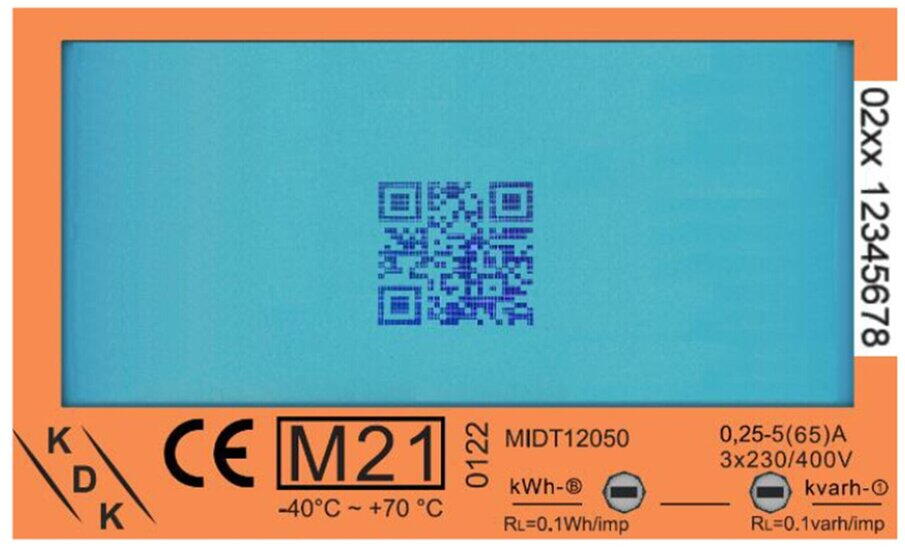

Below you will find a QR code for the explanatory video on how to activate Bluetooth and the options via the app:

7.1. Activating the BT interface on the meter

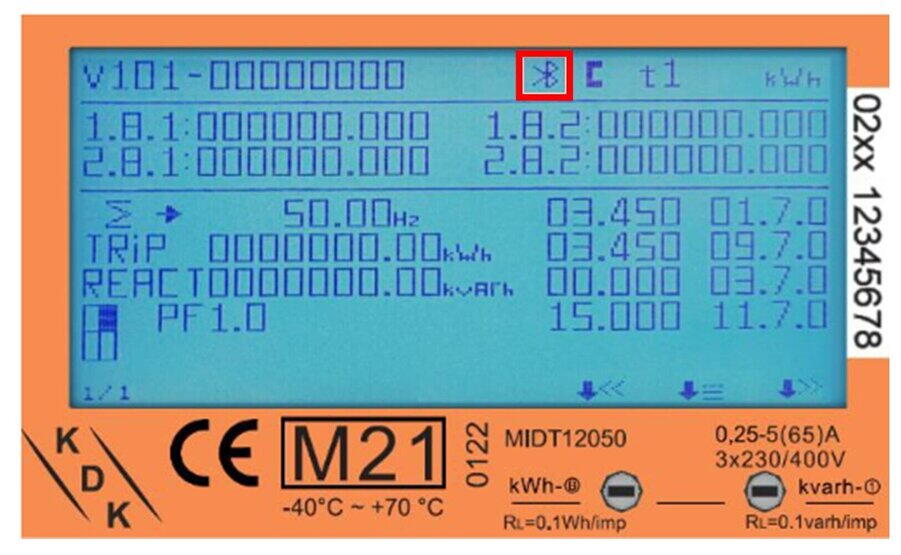

When the arrows >> point to the Bluetooth® icon, briefly press the middle button: |

|

The Bluetooth® interface of the meter is now activated and ready for communication with the KDK Meter Configurator app. To establish the connection with the meter, scan the QR code via the camera of your smartphone or browse the Bluetooth® environment by selecting the corresponding menu item in the app. |

|

When a Bluetooth® connection is established, the Bluetooth® symbol is shown at the top right of the display. |

|

7.2. Bluetooth connection with the meter

-

Start the smartphone app. The desired language can be set in the settings menu (cogwheel) at the top right of the display.

|

|

-

The energy meter can be connected with the Scan Bluetooth or Scan QR function.

-

Scan Bluetooth: The app scans for all Bluetooth measuring devices in the vicinity. Select the correct serial number for the connection.

-

Scan QR: The app opens the camera of the cell phone to scan the QR code on the meter display. As soon as the code has been scanned, the meter is connected.

-

7.3. App — Device page

The energy meter is now connected to the smartphone app. The meter type, serial number, software version and checksums are displayed on the device page.

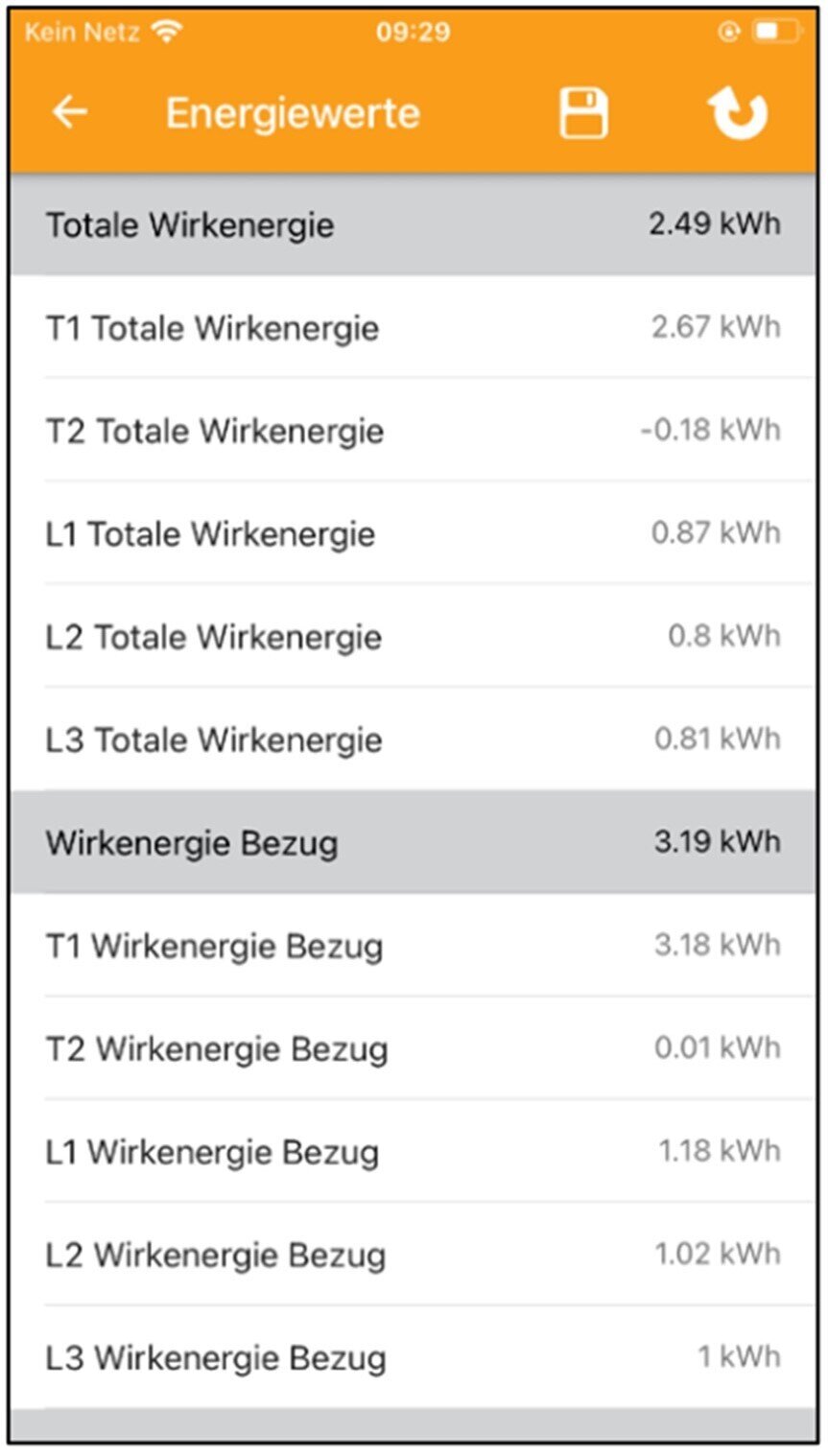

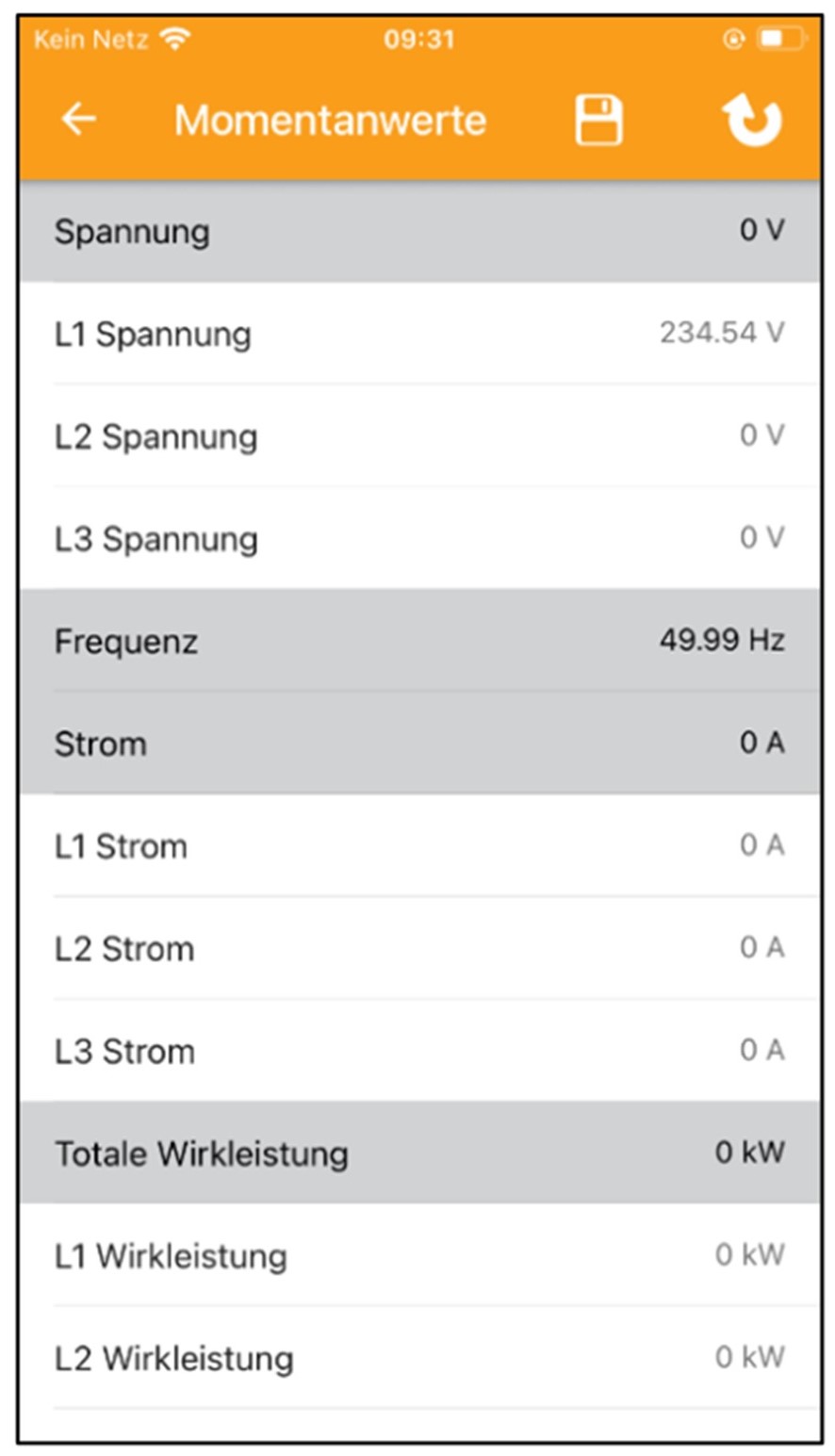

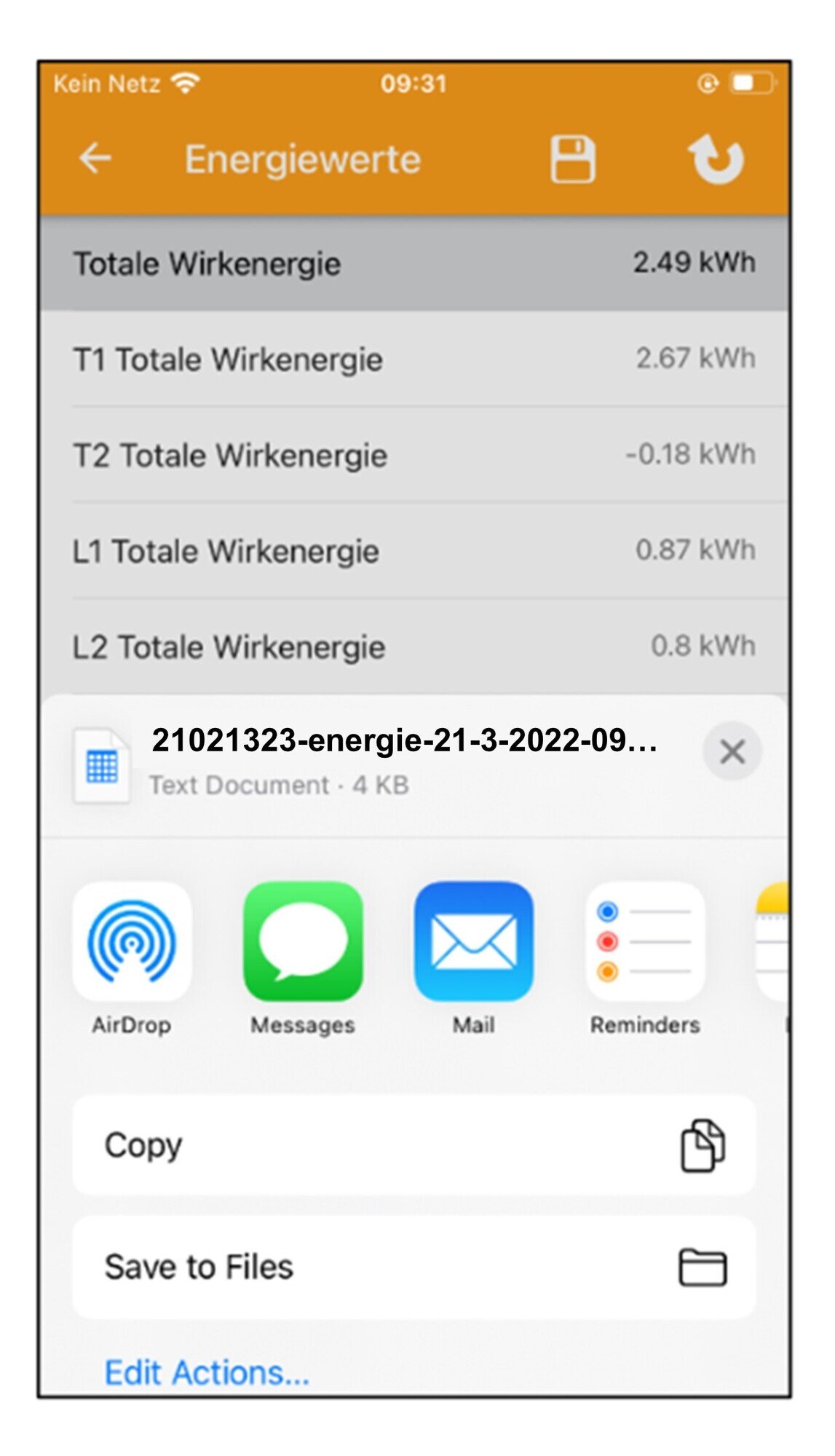

7.4. App — Read out the meter data

All energy values can be found under "Energy" and all instantaneous values under "Instantaneous". Refresh the data using the refresh arrow in the top right-hand corner.

|

|

Save the data using the electrical energy storage icon in the top right-hand corner. The data can be saved locally on the smartphone or forwarded via various channels such as e-mail, Bluetooth or other programs.

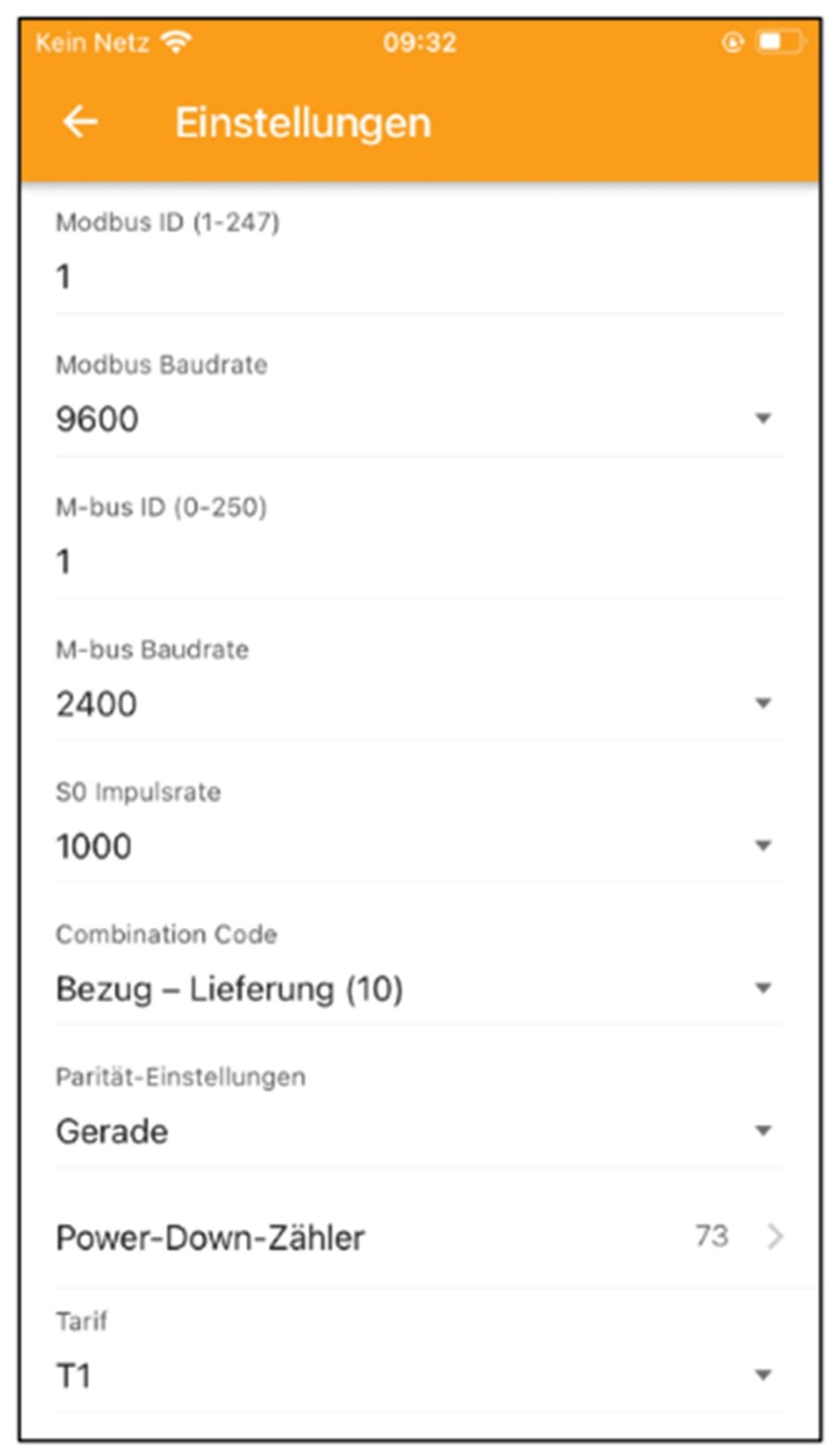

7.5. App — Change meter parameters

Settings can be selected individually and/or saved all at once.

-

Select the settings you want to change. The changed settings are highlighted in green.

-

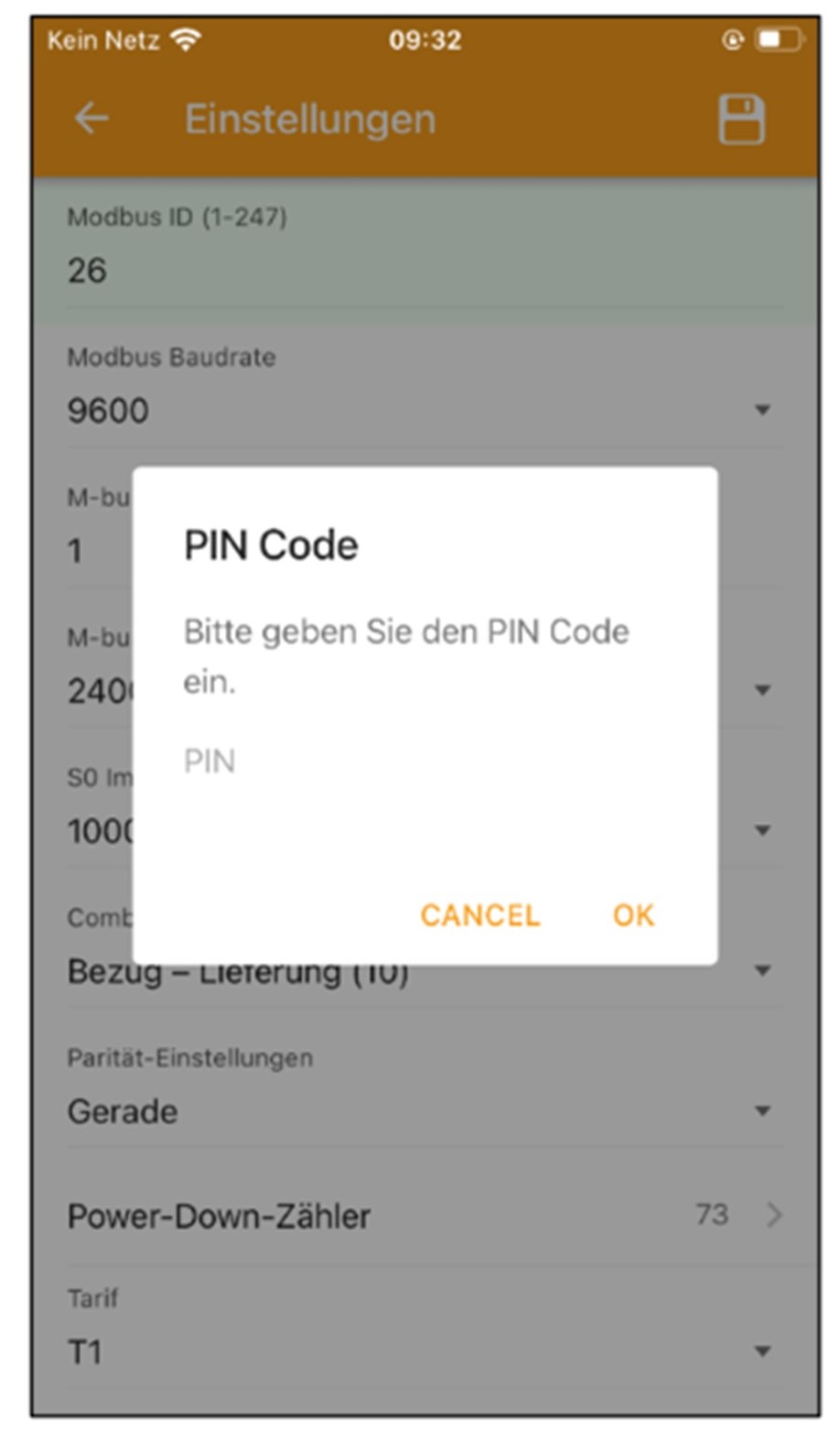

Save the values via the storage disk in the top right-hand corner.

-

A pop-up menu for the password appears first. By default, the password is always 0000.

-

The password can only be changed on the meter using the buttons. After entering the correct password, the new settings are saved in the meter.

|

|

The following configuration settings must be used for use with FEMS:

- RS485 Modbus address grid connection point

-

005

- RS485 Modbus address PV generation

-

006

RS485 Modbus address further

Generator/Consumer load:: 007… 246

- Baud rate for communication

-

9600

- Parity

-

None

8. Troubleshooting

| Problem | Possible cause | Check/solution |

|---|---|---|

The red consumption LED on the front is not flashing or the meter is not counting up. |

There is no load connected to the meter or the load on the line is very low. |

Connect a consumer load to the meter and use a measuring device e. g. ammeter to measure whether the load is present and the LED is flashing. |

The S0 pulse output is not working. |

The pulse output is not connected correctly (polarity) or is not supplied with DC voltage. |

Use a measuring device to check whether the external voltage source (Ui) is 5-27 V DC. Check whether the connection is correct: The 5-27 V DC should be connected to the collector connection (pin 4 or 6 (+)) and the signal line (S) to the emitter connection (pin 5 (-)). |

If none of the above points have led to a solution, please contact technical support. |

||

The configuration is now complete.