FENECON Commercial 92 — Assembly and Operating Instructions

1. About these instructions

Personnel must have carefully read and understood these installation and service instructions before starting any work.

1.1. Manufacturer

FENECON GmbH

Gewerbepark 6

94547 Iggensbach

Germany

Phone: +49 (0) 9903 6280 0

Fax: +49 (0) 9903 6280 909

E-mail: service@fenecon.de

Internet: www.fenecon.de

1.2. Formal information on installation and service instructions

© FENECON GmbH, 2025

All rights reserved.

Reprinting, even in part, is only permitted with the permission of FENECON GmbH.

1.3. Version/revision

Version/Revision |

Change |

Date |

Name |

2024.08.01 |

Draft initial creation |

08/08/2024 |

FENECON FT |

2024.10.01 |

Publication on docs.fenecon.de |

01/10/2024 |

FENECON PM |

2025.1.1 |

Integration fire department notice |

27/01/2025 |

FENECON PM |

2025.8.1 |

Integration split base |

01/08/2025 |

FENECON TK/MR |

2025.11.01 |

Integration flood warning |

03/11/2025 |

FENECON PM |

1.4. Symbol conventions

|

||

|

||

|

||

|

1.5. Structure of warning notices

Warning notices protect against possible personal injury and damage to property if observed and classify the magnitude of the danger by means of the signal word.

|

Source of the danger

|

Danger sign

The danger sign indicates warnings that warn of personal injury.

Source of danger

The source of danger indicates the cause of the hazard.

Possible consequences of non-compliance

The possible consequences of ignoring the warning are e. g. crushing, burns or other serious injuries.

Measures/prohibitions

Measures/prohibitions include actions that must be taken to avoid a hazard (e.g. stopping the drive) or that are prohibited to avoid a hazard.

1.6. Terms and abbreviations

The following terms and abbreviations are used in the installation and service instructions:

| Term/Abbreviation | Meaning |

|---|---|

AC |

Alternating Current |

BHKW |

Combined heat and power plant (CHP) |

BMS |

Battery Management System |

DC |

Direct Current |

EMS |

Energy Management System |

Energy-Meter |

Electricity meter for the Inverter at the grid connection point |

FEMS |

FENECON Energy Management System |

MPPT |

Maximum Power Point Tracking — Finder for the maximum power point |

GCP |

Grid connection point |

CPC |

Circuit protective conductor |

PV |

Photovoltaic |

RTE |

Round-Trip-Efficiency (RTE) |

SG-Ready |

Smart-Grid-Ready — Preparation of the Heat pump for external control |

SoC |

State of Charge |

SoH |

State of Health — Ageing condition |

VDE |

Verband der Elektrotechnik Elektronik Informationstechnik e. V. |

Widget |

Component of online monitoring |

1.7. Scope of delivery

| Item | Component | Amount | Comment |

|---|---|---|---|

1 |

KACO 92 kW — Inverter |

1 |

|

2 |

FENECON Commercial — BMS box (incl. FENECON Energy Management System) |

1 |

|

3 |

FENECON Commercial — Parallel switch box |

1 |

|

4 |

FENECON Commercial — Extension Box |

1 |

up to 4, depending on the system configuration |

5 |

FENECON BMS box |

1 |

per battery tower |

6 |

FENECON Battery Module |

15 |

per battery tower, depending on the ordered capacity |

7 |

FENECON Base (included with FENECON BMS box) |

1 |

per battery tower |

8 |

KDK 2PU CT |

1 |

| Component | Comment |

|---|---|

Installation and service instructions FENECON Commercial |

Instructions for the installer |

Quick start guide FENECON Commercial |

Quick start guide for the installer |

Operating instructions FENECON Commercial |

Instructions for the user/end customer |

2. Safety

2.1. Intended use

The FENECON electrical energy storage system is used for the storage of electrical energy in rechargeable lithium iron phosphate battery modules (charging) and the provision of electrical energy (discharging). This charging and discharging process takes place via a connected inverter. The system must only be used in compliance with the permissible technical data (see section Technical data).

FENECON power storage systems consist of various modules. In particular, these include a BMS (battery management system), the FENECON Energy Management System (FEMS), battery modules and bases. All processes of the electricity storage system are monitored and controlled by the FEMS.

Any other use is not an intended use.

2.2. Reasonably foreseeable misuse

All applications that do not fall within the scope of the intended use are considered misuse.

Work on live parts is generally not permitted. Electrical work must only be carried out by qualified electricians.

The following safety rules must be observed for all work on electrical components:

-

Disconnect.

-

Secure against restarting.

-

Check that there is no voltage.

-

Earth and short-circuit.

-

Cover or shield neighboring live parts.

|

Non-compliance with the safety rules is considered a reasonably foreseeable misuse. |

Other misuses include in particular:

-

Improper transportation, installation or assembly at a location, trial operation or operation that could damage the system.

-

Change in the specified technical characteristics, including the individual components.

-

Change or deviation of the connected load.

-

functional or structural changes.

-

Operating the product in a faulty or defective condition.

-

Improper repairs.

-

Operation without protective devices or with defective protective devices.

-

Disregarding the information in the original installation and service instructions.

-

Fire, open light and smoking in the vicinity of the storage system.

-

Insufficient ventilation at the installation site.

-

Unauthorized changes and actions to the electrical energy storage system.

-

Use as mobile energy storage.

-

Direct use in a PV system (integration via an AC-coupled grid is possible).

2.3. Area of application — Electromagnetic compatibility (EMC)

The low-voltage equipment is intended for use in the following areas of application:

-

General public (public)

Use in other areas of application is not in accordance with the intended use.

2.4. Qualification of the staff

Qualified personnel must be deployed for the intended use, installation and maintenance of the system. The area of responsibility, competence and supervision of the personnel must be precisely regulated by the operator.

2.4.1. Trained electricians

Skilled electrical personnel include persons who:

-

are able to carry out work on electrical systems due to their technical training, knowledge and experience as well as knowledge of the relevant standards and regulations.

-

have been commissioned and trained by the operator to carry out work on electrical systems and equipment of the battery system.

-

are familiar with how the battery system works.

-

recognize hazards and prevent them by taking appropriate protective measures.

2.5. General information on the FENECON electrical energy storage system

The product must be positioned in such a way that sufficient room for movement can be guaranteed for service and maintenance personnel in every phase of the product’s life. The service life of the product depends on the service life and maintenance intervals carried out by qualified personnel. The service life is particularly influenced by preventive maintenance and servicing.

-

The battery modules must only be installed and the cable connections made by qualified electricians.

-

The electrical energy storage system must only be used under the specified charging/discharging conditions (see section Technical data).

-

Keep the electrical energy storage system away from children and animals.

-

Do not connect the plug contacts of the BMS box in reverse.

-

Do not short-circuit battery modules.

-

Only use the battery modules as intended.

-

Improper use can lead to overheating, explosion or fire of the battery modules.

-

-

Read the instructions for installation and operation to avoid damage due to incorrect operation.

-

The battery modules may have insufficient cell voltage after a long storage period. If this is the case, please contact the service department

-

Do not expose the battery modules to high voltages.

-

Place the battery modules on level surfaces.

-

Do not place any objects on the FENECON battery towers.

2.5.1. Environmental influences

-

Keep the electrical energy storage system away from water sources.

-

Do not immerse the electrical energy storage system in water, moisten it or touch it with wet hands.

-

Set up/store the electrical energy storage system in a cool place.

-

Do not heat the electrical energy storage system.

-

Do not expose the electrical energy storage system to open fire.

-

Do not set up or use the electrical energy storage system near open fires, heaters or high-temperature sources.

-

The heat can cause insulation to melt and the safety ventilation to be damaged. This can lead to overheating, explosion or fire on the battery modules.

-

-

No soldering work must be carried out on the electrical energy storage system. Heat introduced during soldering can damage the insulator and the safety venting mechanism and lead to overheating, explosion or fire of the battery modules.

2.5.2. Mechanical influences

-

The battery modules must not be dismantled or modified. The battery modules contain a safety mechanism and a protective device, damage to which can lead to overheating, explosion or fire of the battery modules.

-

Do not step on the electrical energy storage system.

-

Do not attempt to crush or open battery modules.

-

Do not apply any mechanical force to the electrical energy storage system.

-

The battery modules can be damaged and short circuits can occur, which can lead to overheating, explosion or fire of the battery modules.

-

-

Do not throw or drop parts of the power storage system.

-

Do not use defective or dropped battery modules.

-

-

Do not use the electrical energy storage system if changes in color or mechanical damage are detected during assembly, charging, normal operation and/or storage.

-

If the protective devices are damaged, abnormal charging currents and voltages can cause a chemical reaction in the battery modules, which can lead to overheating, explosion or even fire in the battery modules.

2.5.3. Installation, operation and maintenance

|

When carrying out maintenance, servicing and cleaning work, ensure that the product is switched off in a safe manner and secured against being switched on again. In addition, all instructions in these installation and service instructions must be followed. |

Always observe the following safety instructions when installing, operating or maintaining the battery modules:

-

Installation/maintenance work and making cable connections must only be carried out by qualified personnel (trained electricians).

-

During maintenance work, stand on dry insulating objects and do not wear any metal objects (e.g. watches, rings and necklaces) during maintenance work/operation.

-

Use insulated tools and wear personal protective equipment.

-

Do not touch two charged contacts with a potential difference.

-

Measure the battery voltage with a multimeter and ensure that the output voltage is 0 V in off mode.

-

If an anomaly is detected, switch off the battery tower immediately.

-

Only continue the maintenance work after the causes of the anomaly have been eliminated.

-

The battery modules can cause electric shock and burns due to high short-circuit currents.

-

Do not touch the battery module connectors (+) and (-) directly with a wire or metal object (e. g. metal chain, hairpin). Excessive current can be generated in the event of a short circuit, which can lead to overheating, explosion or fire of the battery modules.

2.5.4. Fire protection

-

Do not expose the electrical energy storage system to direct sunlight.

-

Avoid contact with conductive objects (e. g. wires).

-

Keep heat and fire sources, flammable, explosive and chemical materials away from the electrical energy storage system.

-

Explosion hazard: Do not dispose of battery modules in a fire!

2.5.5. Storage

-

Area: Fireproof indoors/outdoors with suitable weather protection.

-

Air temperature: -20 °C to 40 °C.

-

Relative humidity: max. 50 % at +40 °C.

-

Do not store battery modules (lithium iron phosphate batteries) with flammable or toxic objects.

-

Store battery modules with safety defects separately from undamaged battery modules.

|

Storage longer than 12 months

|

2.6. Operating resources

2.6.1. Electrolyte solution of the battery modules

-

Electrolyte solution is used in the battery modules (lithium iron phosphate).

-

The electrolyte solution in the battery modules is a clear liquid and has a characteristic odor of organic solvents.

-

The electrolyte solution is flammable.

-

The electrolyte solution in the battery modules is corrosive.

-

Do not inhale the vapors.

-

If the electrolyte solution is swallowed, induce vomiting.

-

Leave the contaminated area immediately after inhaling vapors.

-

Eye and skin contact with leaked electrolyte solution must be avoided.

-

Contact with electrolyte solution can cause severe burns to the skin and damage to the eyes.

-

After skin contact: Immediately wash skin thoroughly with neutralizing soap and consult a doctor if skin irritation persists.

-

After eye contact: Immediately flush eye(s) with running water for 15 minutes and seek medical advice.

-

|

Delayed treatment can cause serious damage to health. |

2.7. Residual risk

|

Warning of electrical voltage Work on electrical equipment may only be carried out by qualified electricians from the manufacturer or by specially authorized, trained electricians and in compliance with the safety regulations. |

|

Unknown fault messages Unknown faults and attempts to rectify them can lead to damage to the product. |

|

All doors, emergency exits and areas around the electrical energy storage system must remain clear; do not obstruct escape routes! |

|

The condition of the floor outside the storage system is the responsibility of the user. However, the housing is sealed so that no electrolyte can escape. |

2.8. Behavior in emergency situations

Proceed as follows in emergency situations:

-

Disconnect the electrical energy storage system from the grid.

-

Leave the zone of danger immediately.

-

Secure the danger zone.

-

Inform the persons responsible.

-

Call a doctor if necessary.

2.9. Pictograms

Pictograms on the system indicate dangers, prohibitions and instructions. Illegible or missing pictograms must be replaced by new ones.

| Pictogram | Meaning | Description |

|---|---|---|

Warning of dangerous electrical voltage |

Pictogram on the enclosure, and marking of components which do not clearly show that they contain electrical equipment which may be the cause of a risk of electric shock. |

|

General warning sign |

||

Battery charging hazard warning |

Pictogram on housing and marking of components that do not clearly indicate that they contain electrical equipment that may give rise to a battery charging hazard. |

|

No open flames; fire, open sources of ignition and smoking prohibited |

Pictogram on the enclosure and marking of components that do not clearly indicate that they contain electrical equipment that may present a risk of open flames, fire, open sources of ignition and smoking. |

|

Protective earthing symbol |

||

Separate collection of electrical and electronic equipment |

||

Note instructions |

||

Wear protective headgear |

||

Wear protective footwear |

||

Wear protective gloves |

||

CE mark |

||

Product is recyclable. |

2.10. Operating materials/equipment

2.10.1. Electrolyte solution of the battery modules

-

Electrolyte solution is used in the battery modules (lithium iron phosphate).

-

The electrolyte solution in the battery modules is a clear liquid and has a characteristic odor of organic solvents.

-

The electrolyte solution is flammable.

-

The electrolyte solution in the battery modules is corrosive.

-

Contact with electrolyte solution can cause severe burns to the skin and damage to the eyes.

-

Do not inhale the vapors.

-

If the electrolyte solution is swallowed, induce vomiting.

-

Leave the contaminated area immediately after inhaling vapors.

-

Eye and skin contact with leaked electrolyte solution must be avoided.

-

After skin contact: Immediately wash skin thoroughly with neutralizing soap and consult a doctor if skin irritation persists.

-

After eye contact: Immediately flush eye(s) with running water for 15 minutes and seek medical advice.

-

Delayed treatment can cause serious damage to health.

2.10.2. Electrical equipment

-

Work on electrical equipment may only be carried out by qualified electricians.

-

The five safety rules must be observed for all work on electrical components:

-

Disconnect.

-

Secure against restarting.

-

Check that there is no voltage.

-

Earth and short-circuit.

-

Cover or shield neighboring live parts.

-

-

Maintenance work may only be carried out by trained specialist personnel (service personnel).

-

Before starting work, carry out visual checks for insulation and housing damage.

-

The system must never be operated with faulty or non-operational electrical connections.

-

To avoid damage, lay supply lines without crushing and shearing points.

-

Only insulated tools may be used for maintenance on uninsulated conductors and terminals.

-

Switch cabinets (e. g. inverter housing) must always be kept locked. Only authorized personnel with appropriate training and safety instructions (e. g. service personnel) should be allowed access.

-

Observe the inspection and maintenance intervals for electrical components specified by the manufacturer.

-

To avoid damage, lay supply lines without crushing and shearing points

-

If the power supply is disconnected, specially marked external circuits may still be live!

-

Some equipment (e. g. inverters) with an electrical intermediate circuit can still carry dangerous residual voltages for a certain time after disconnection. Before starting work on these systems, check that they are voltage-free.

2.11. Personal protective equipment

Depending on the work carried out on the system, wear PPE (personal protective equipment):

-

Protective footwear

-

Protective gloves, cut-resistant if necessary

-

Protective eyewear

-

Protective headgear

2.12. Spare and wear parts

The use of spare and wear parts from third-party manufacturers can lead to risks. Only original parts or spare and wear parts approved by the manufacturer may be used. The instructions for spare parts must be observed. Further information can be found in the wiring diagram.

|

Further information must be requested from the manufacturer. |

2.13. IT security

FENECON energy storage systems and their applications communicate and operate without internet connection. The individual system components (inverters, batteries, etc.) are not directly connected to the internet or accessible from the internet. Sensitive communications via the internet are processed exclusively via certificate-based TLS encryption.

Access to the programming levels is not barrier-free and is accessible at different levels depending on the qualifications of the operating personnel. Safety-relevant program changes require additional verification.

FENECON processes energy data of European customers exclusively on servers in Germany and these are subject to the data protection regulations applicable in this country.

The software used is checked using automated tools and processes established during development in order to keep it up to date and to rectify security-relevant vulnerabilities at short notice. Updates for FEMS are provided free of charge for life.

3. Technical data

3.1. General

| Description | Value/dimension | |

|---|---|---|

Installation/ |

IP classification |

IP55 |

Operating altitude above sea level |

≤ 2,000 m |

|

Installation/operating temperature |

-20 °C to +60 °C |

|

Relative humidity (operation/storage) |

0 to 100 % |

|

Battery operating temperature |

-10 °C to +50 °C |

|

Optimal operating temperature of the battery |

15 °C to +30 °C |

|

Cooling |

Temperature-controlled fan |

|

Loudness |

< 60 dB |

|

Certification/guideline |

Overall system |

CE |

Inverter |

VDE 4105:2018-11 |

|

Battery |

UN38.3 |

|

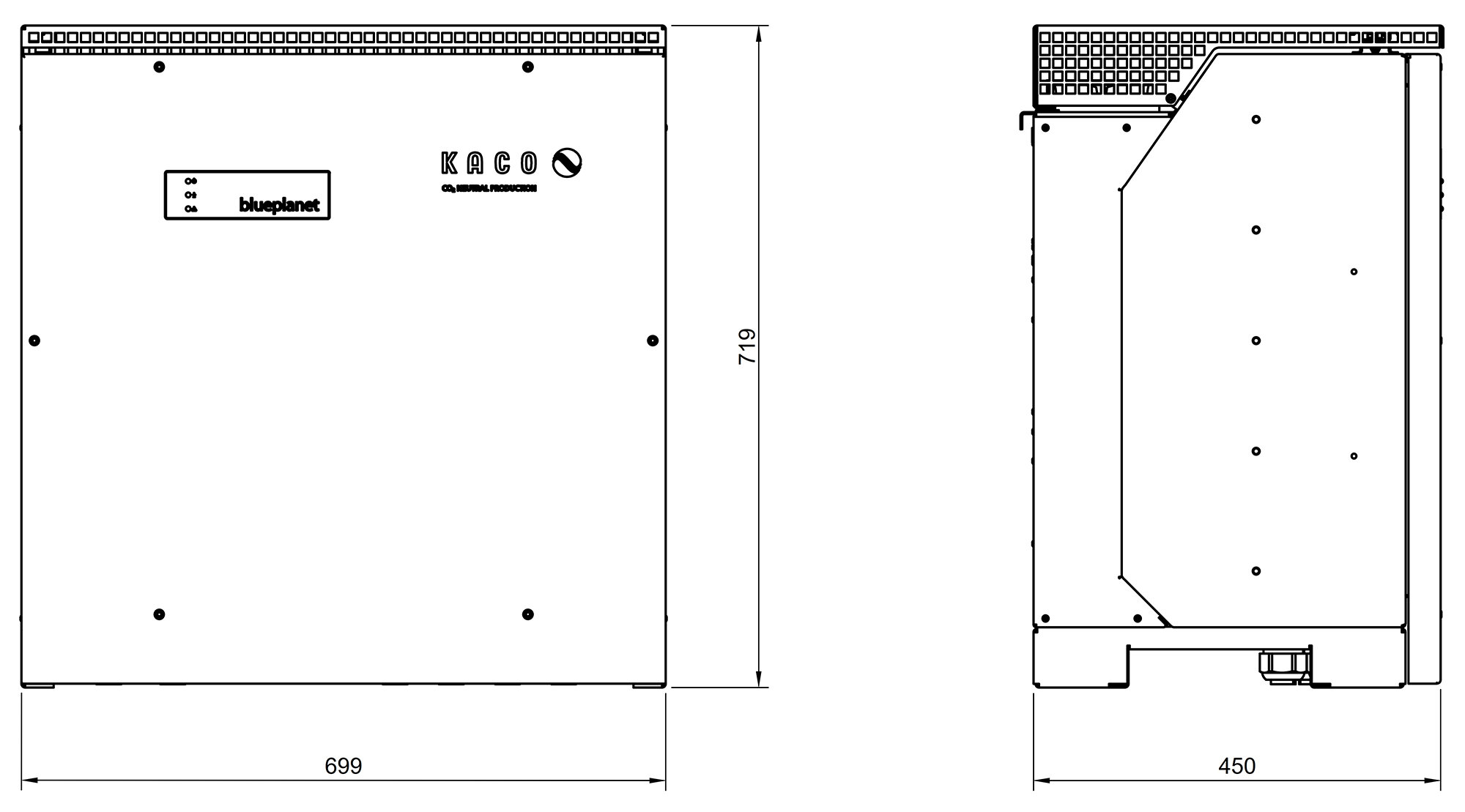

3.2. Technical data — Inverter

| Description | Value/dimension | |

|---|---|---|

Inverter model |

KACO blueplanet gridsave 92.0 TL3-S |

|

AC connection |

Grid connection |

400 V, 3L/PE, 50/60 Hz |

Rated voltage |

400 V |

|

Rated power |

92000 VA |

|

Rated current |

3 x 132.3 A |

|

Efficiency |

Max. Efficiency |

Charging: 98.5 % — Discharging: 98.7 % |

General |

Protection specification |

IP66 |

Width | Depth | Height |

699 | 450 | 719 mm |

|

Weight |

80 kg |

|

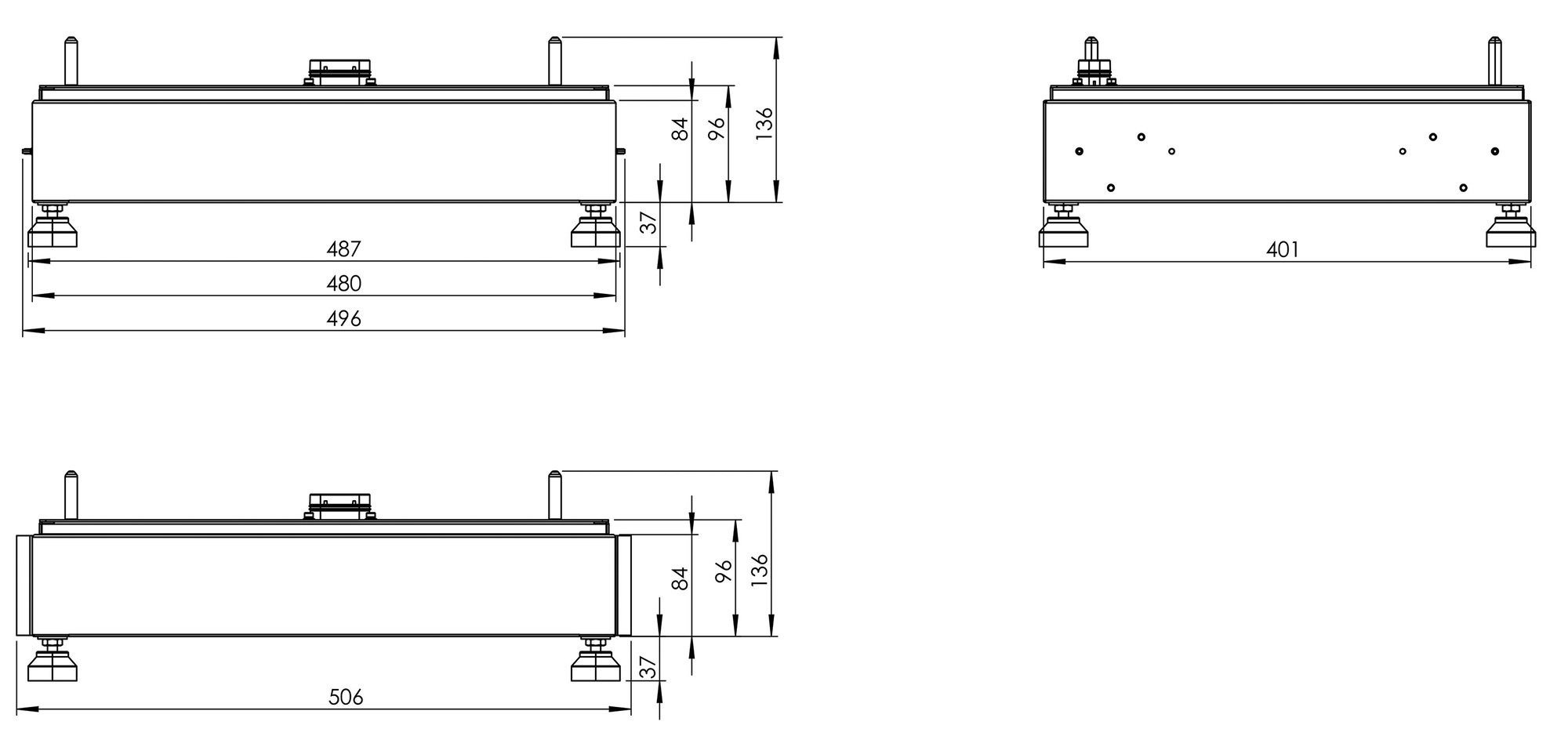

3.3. Technical data — FENECON Commercial 92 — EMS box

| Description | Value/dimension |

|---|---|

Operating voltage DC |

224 V to 672 V |

Max. Current (battery) |

50 A |

Operating temperature |

-10°C to 50°C |

Protection specification |

IP55 (plugged in) |

Input voltage |

100 V to 240 V/1.8 A/50 Hz to 60 Hz |

Width | Depth | Height |

506 | 401 | 157 mm |

Weight |

12 kg |

Installation |

stackable |

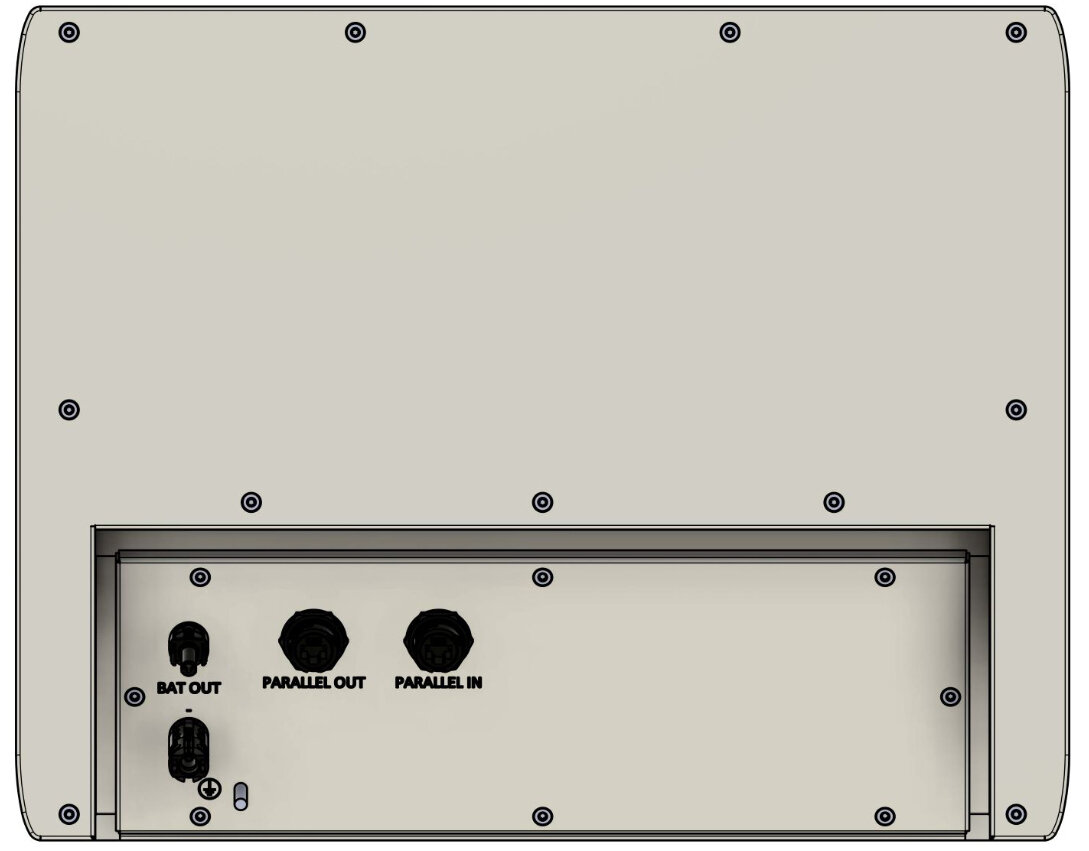

3.3.2. EMS box — Pin assignment

| Item | Description |

|---|---|

1 |

Battery connection to the inverter (MC4-Evo stor) |

2 |

Communication output for parallel connection of several batteries |

3 |

Customer network connection (LAN) RJ45 (network cable not included in scope of delivery) |

4 |

Communication Inverter, relay outputs; digital inputs (16-pin connector) |

5 |

Power supply FEMS box; potential-free contacts (max. 10 A, measured) (10-pin plug) |

6 |

Earth connection |

7 |

For future applications (not assigned) |

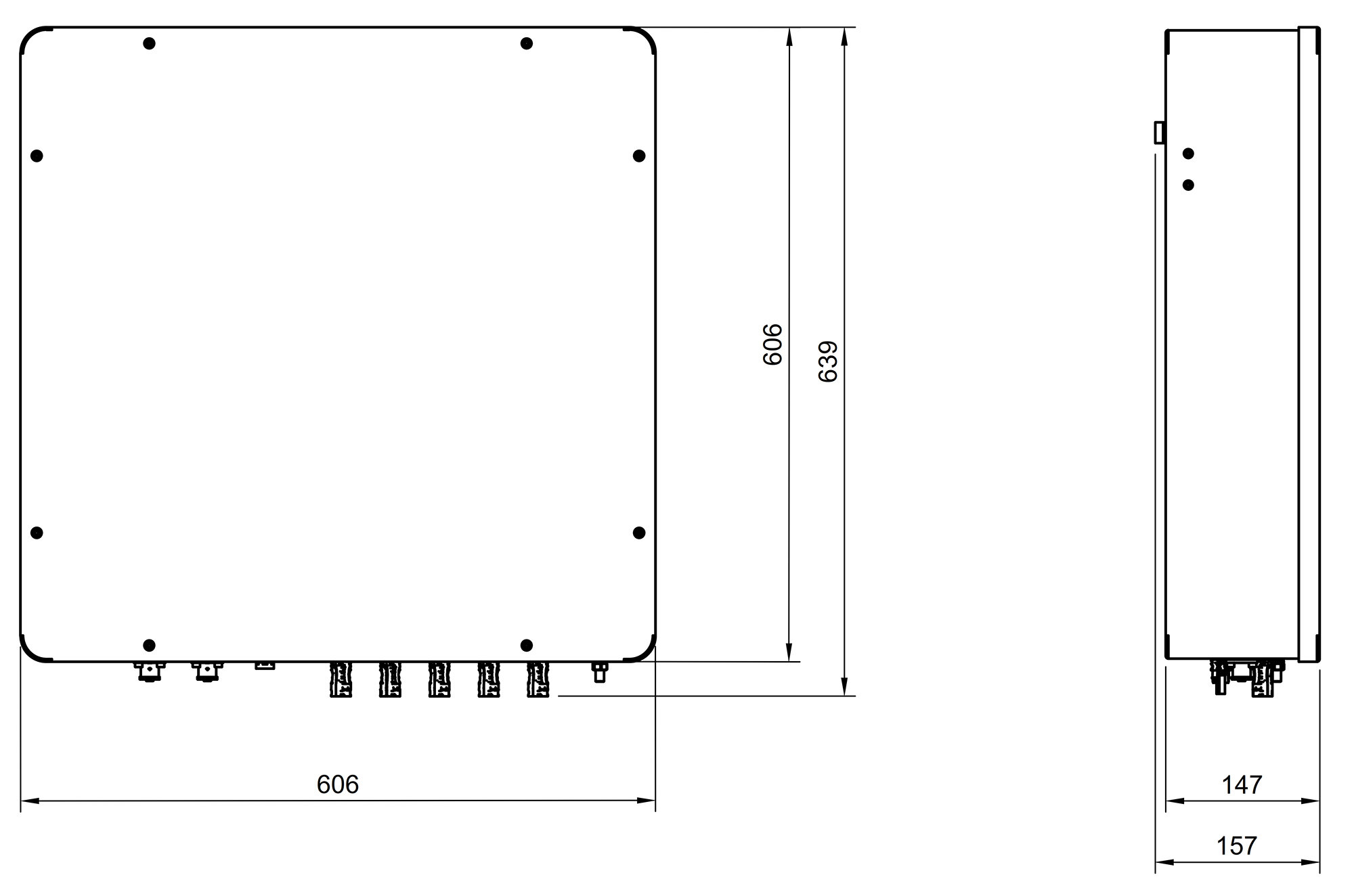

3.4. Technical data — FENECON Commercial 92 — Parallel switch box

| Naming | Value/dimension |

|---|---|

Max. operating voltage |

800 V |

Max. Current (inverter) |

150 A |

Max. Current (battery) |

50 A |

Operating temperature |

-20 °C to 40 °C |

Protection specification |

IP55 |

Width | Depth | Height |

606 | 157 | 639 mm |

Weight |

26 kg |

3.5. Technical data — FENECON Commercial 92 — Extension box

| Naming | Value/dimension |

|---|---|

Operating voltage DC |

224 V to 672 V |

Max. Current (battery) |

50 A |

Operating temperature |

-10 °C ~ 50 °C |

Protection specification |

IP55 (plugged in) |

Width | Depth | Height |

506 | 401 | 157 mm |

Weight |

9 kg |

Installation |

stackable |

3.5.2. Extension box — Terminal assignment

| Item | Description |

|---|---|

1 |

Battery connection to EMS box in parallel (MC4-Evo stor) |

2 |

Communication output for parallel connection of several battery towers |

3 |

Communication input for parallel connection of several battery towers |

4 |

Earthing connection |

3.6. Technical data — FENECON Commercial 92 — BMS box

| Description | Value/dimension |

|---|---|

Max. operating voltage range |

224 V to 672 V |

Max. input/output current |

50 A |

Optimal operating temperature |

15 to 30 °C |

Operating temperature range |

-20 to 55 °C |

Protection specification |

IP55 (stacked) |

Width (incl. side panel)| Depth | Height |

506 | 401 | 143 mm |

Weight |

13 kg |

Installation |

stackable/wall-mounted |

4. General description

FENECON Commercial 92 is an AC-coupled electrical energy storage system that can build its own power grid for consumer loads. Lithium iron phosphate batteries (LiFePO4) are used in this modular system for storing electrical energy.

4.1. System configuration — General overview

4.1.1. System structure as an AC system

| Item | Description |

|---|---|

1 |

Grid |

2 |

Bi-directional meter |

3 |

Energy meter |

4 |

3-Phase Sensor or with PV inverter App |

5 |

PV inverter |

6 |

PV system |

7 |

FENECON Commercial 92 battery towers |

8 |

Inverter |

4.1.2. Required components

Depending on the system configuration, the following components are required. If up to five battery towers are connected in parallel, ensure that 15 battery modules are installed in each battery tower.

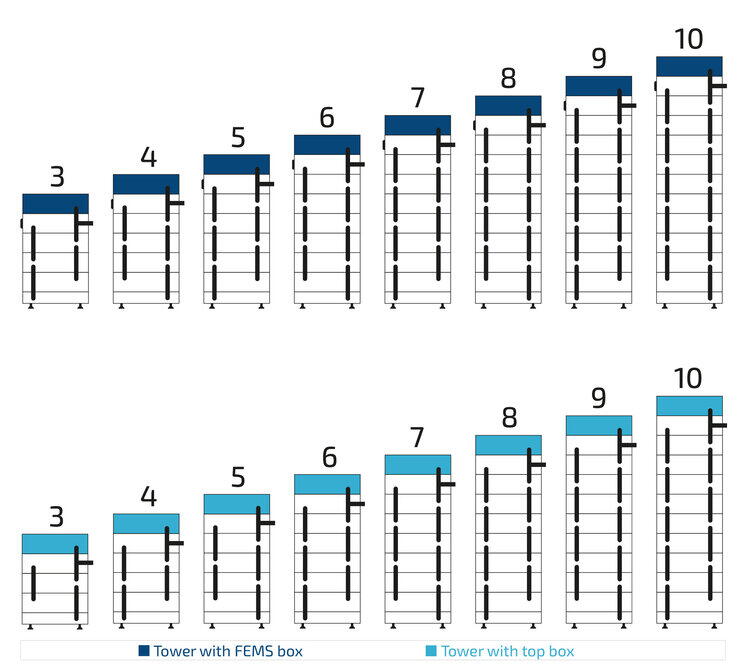

Number of battery towers |

Number of battery modules max. |

BMS box |

EMS box |

Parallel switch box |

Extension box |

2 |

30 |

1 |

1 |

1 |

1 |

3 |

45 |

1 |

1 |

1 |

2 |

4 |

60 |

1 |

1 |

1 |

3 |

5 |

75 |

1 |

1 |

1 |

4 |

5. Installation preparation

5.1. Scope of delivery

5.1.2. FENECON Commercial 92 — EMS box

| Image | Amount | Description | Item no. |

|---|---|---|---|

|

1 |

FENECON Commercial 92 — EMS box |

FEC010 |

|

2 |

Side panel |

Part of complete set |

|

2 |

Harting housing with cable gland (13-21 mm), multi-hole seal (4 x 8 mm) |

Part of complete set |

|

1 |

Harting socket, 10-pin |

Part of complete set |

|

1 |

Harting insert, 16-pin (assembled) |

Part of complete set |

|

1 |

Jumper plug |

Part of complete set |

|

2 |

Network connector housing |

Part of complete set |

|

5 |

Filler plug, 8 mm |

Part of complete set |

|

2 |

Filler plug, 10 mm |

Part of complete set |

|

1 |

Battery cable set, 10 m |

FEC037 |

|

1 |

Installation and service instructions (for installers) |

|

|

1 |

Operating instructions (for end customers) |

|

|

1 |

Quick start guide (for installers) |

5.1.3. FENECON Commercial 92 — Parallel switch box

| Image | Amount | Description | Item no. |

|---|---|---|---|

|

1 |

FENECON Commercial 92 — Parallel switch box |

In combination with inverter |

|

1 |

Wall bracket |

FEC031 |

|

4 |

Anchor with screw and washer |

Part of complete set |

|

1 |

Two DC cables, 3 m |

FEC034 |

|

1 |

Communication cable — inverter-FEMS box; 10 m |

FEC032 |

|

1 |

Earthing kit |

Part of complete set |

5.1.4. FENECON Commercial 92 — Extension box

| Image | Amount | Description | Item no. |

|---|---|---|---|

|

1 |

FENECON Commercial 92 Extension box |

FEC012 |

|

2 |

Side panel |

FEH059 |

|

2 |

Each set of two DC cables, 10 m |

FEC037 |

|

1 |

Communication cable, 2 m |

FEH059 |

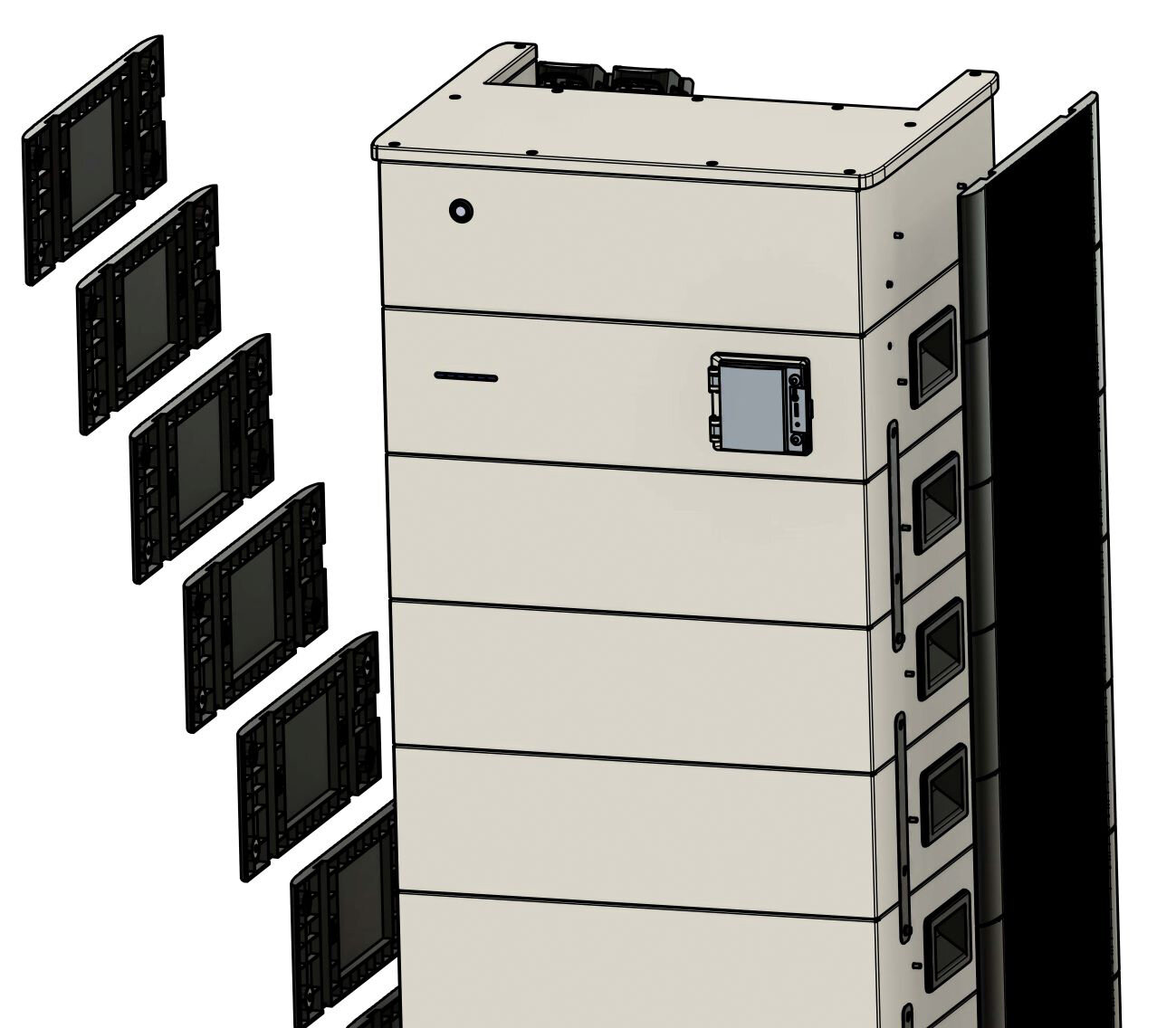

5.1.5. FENECON Commercial 92 — BMS box/base

| Image | Amount | Description | Item no. |

|---|---|---|---|

|

1 |

FENECON Commercial 92 — BMS box |

FEH000 |

|

1 |

Base |

|

|

2 |

Side panel (FENECON Commercial 92 — BMS box) |

FEH051 |

|

2 |

Side panel (base) |

|

|

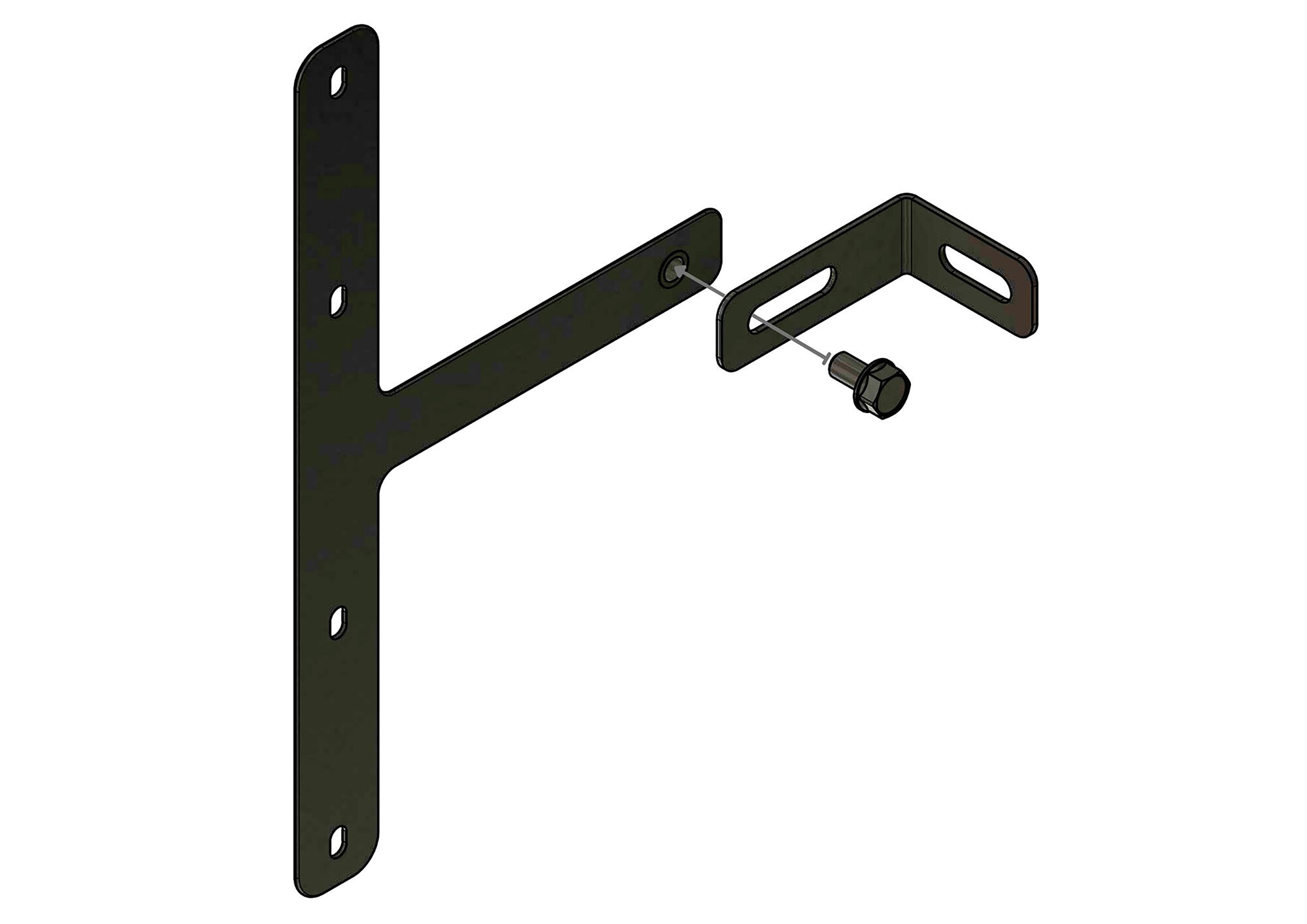

4 |

Wall mounting — Mounting bracket |

Part of complete set |

|

4 |

Wall mounting — Mounting bracket (wall part) |

Part of complete set |

|

4 |

Bolt M4 x 10 |

Part of complete set |

|

4 |

Bolt for wall-mounting M6 x 12 |

Part of complete set |

5.2. Tools required

The following tools are required for assembly of the system components:

| Image | Description | Image | Description |

|---|---|---|---|

|

Pencil |

|

Spirit level |

|

Impact drill or |

|

Screwdriver set |

|

Meter stick |

|

Side cutter |

|

Allen key, 3 mm |

|

Flat spanners |

|

Crimping tool |

|

Multimeter |

|

Pliers for cable glands |

|

Protective eyewear |

|

Safety footwear |

|

Dust mask |

|

Rubber mallet |

|

Vacuum cleaner |

|

Wire stripper |

|

Protective gloves |

|

Torque wrench |

|

Stripping knife |

6. Assembly

|

|

|

|

Suitable protective covers must be fitted! |

The following components must be installed:

-

Inverter

-

Battery tower with base, battery modules, BMS box, and FENECON Commercial 92 EMS box

-

Battery tower with base, battery modules, BMS box and Extension box

-

Before installation, carefully check that the packaging and products are undamaged and that all accessories listed in Chapter 5: [Preparing for installation] are included. If a part is missing or damaged, contact the manufacturer/dealer.

6.1. Assembly — Inverter

|

The safety and installation regulations can be found in the inverter manual. |

6.2. Installation — Battery tower 1 with FEMS box

6.2.1. Safety instructions

|

Electric shock from live parts

|

|

Electric shock in the absence of overvoltage protection

|

|

Fire and explosion

|

|

Fire and explosion with deeply discharged battery modules

|

|

Toxic substances, gases and dusts

|

|

Arcs due to short-circuit currents

|

|

Destruction of a measuring device due to overvoltage

|

|

Hot surfaces

|

|

Weight of the battery modules

|

|

Sand, dust and moisture

|

|

Electrostatic charging

|

|

Cleaning agents

|

|

Installation site

|

|

Installation

|

6.2.2. Conditions at the installation site

Indoor or outdoor installation

We recommend installing the FENECON Commercial 92 — battery towers in a well-ventilated room without external heat sources. However, the battery towers can also be installed outdoors protected from the weather (e. g. garage).

Installation at 2000 m above sea level and in unventilated locations is not permitted.

Also inadmissible installation sites:

-

those with an explosive atmosphere.

-

Places where flammable or oxidizing substances are stored.

-

Wet rooms.

-

Places where salty moisture, ammonia, corrosive vapors or acid can penetrate the system.

The storage system should also be inaccessible to children and animals.

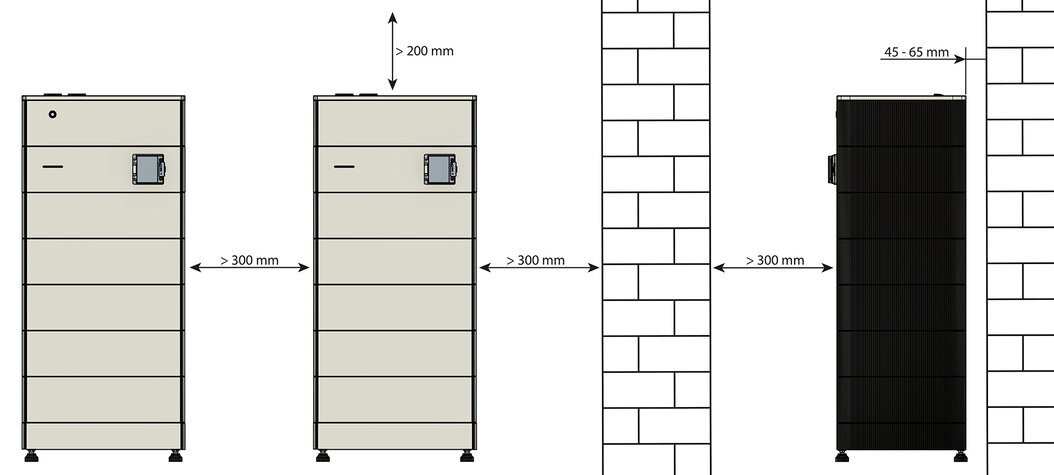

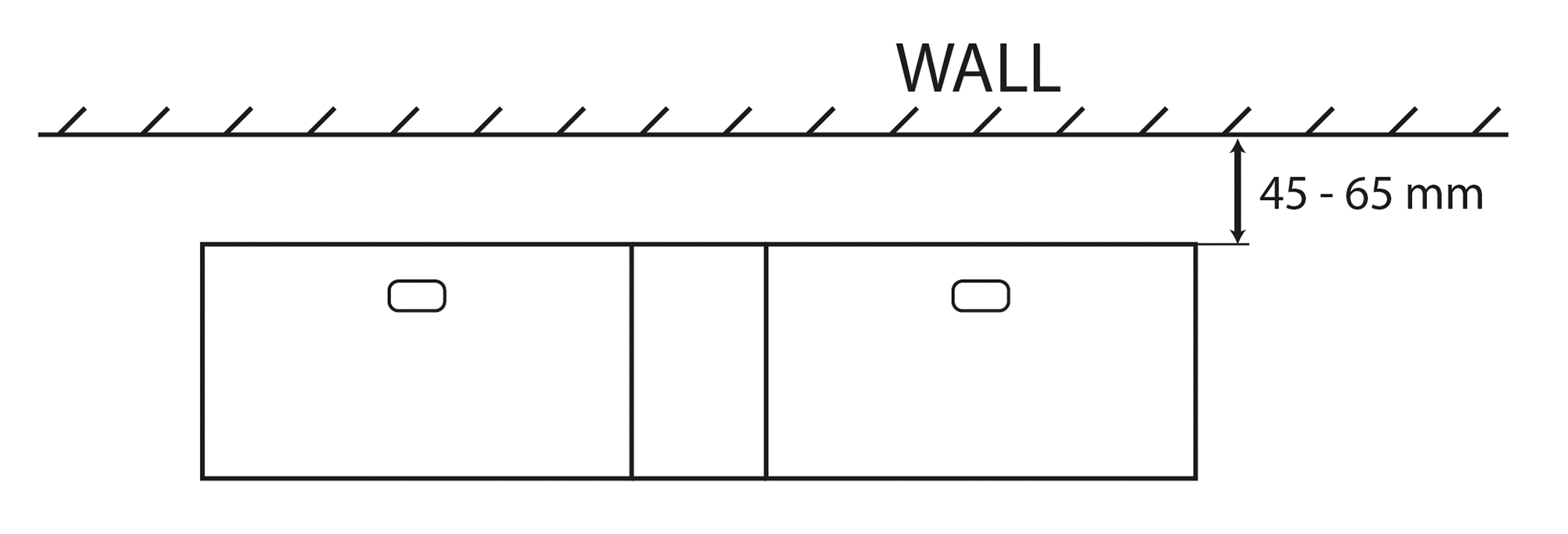

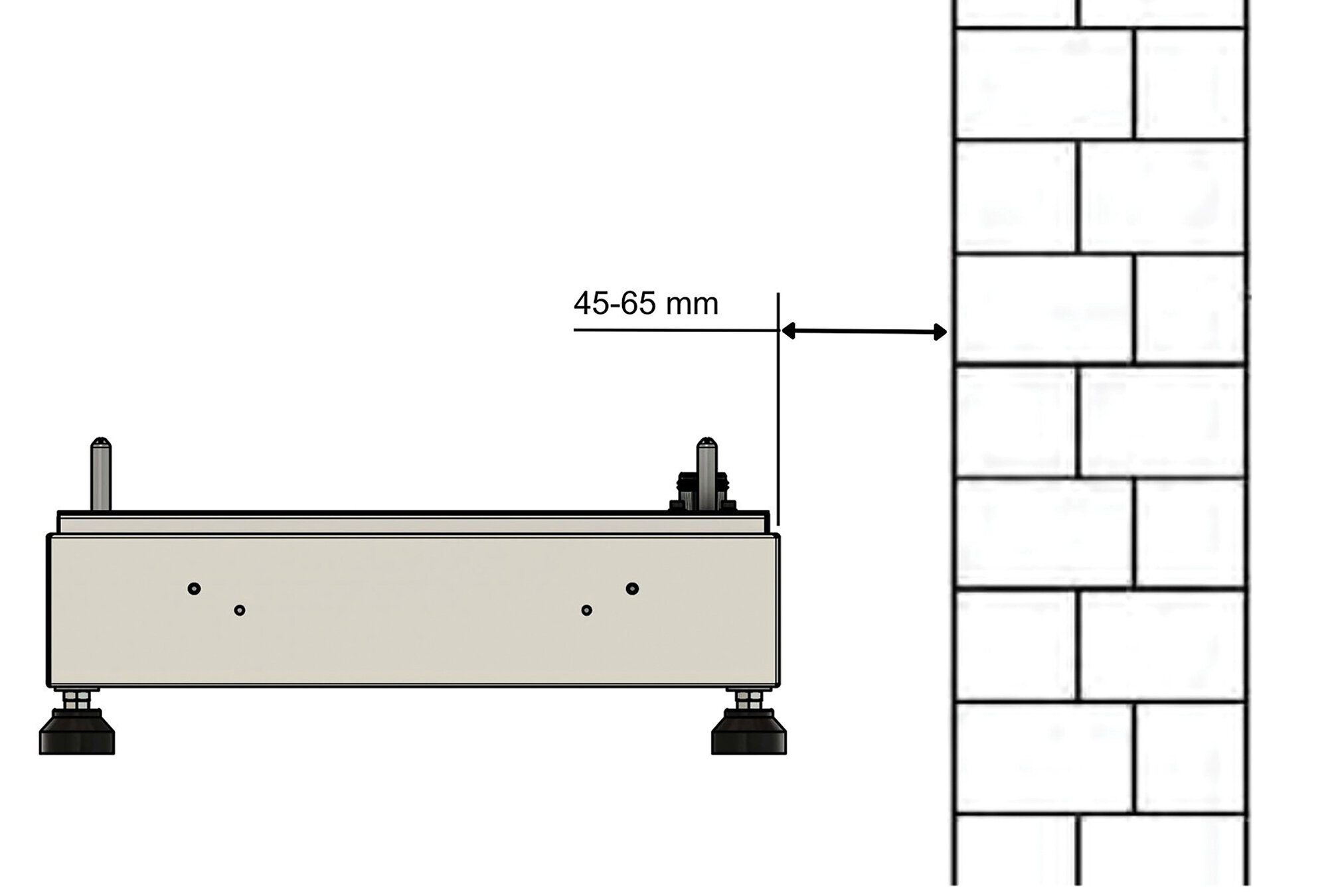

6.2.3. Installation conditions and clearances at the installation site

-

Battery towers must be installed away from direct sunlight and protected from direct rain and snow.

-

In conditions outside the optimum temperature range, the performance of the batteries is reduced. (optimum temperature range: +15 °C to +30 °C)

-

A lateral clearance of 300 mm from a wall and 300 mm between two battery towers is recommended.

-

Clearances of 300 mm from a wall are recommended at the front.

-

A distance of 200 mm from the ceiling is recommended.

|

Falling below the recommended clearances can make installation more difficult and may result in earlier derating. |

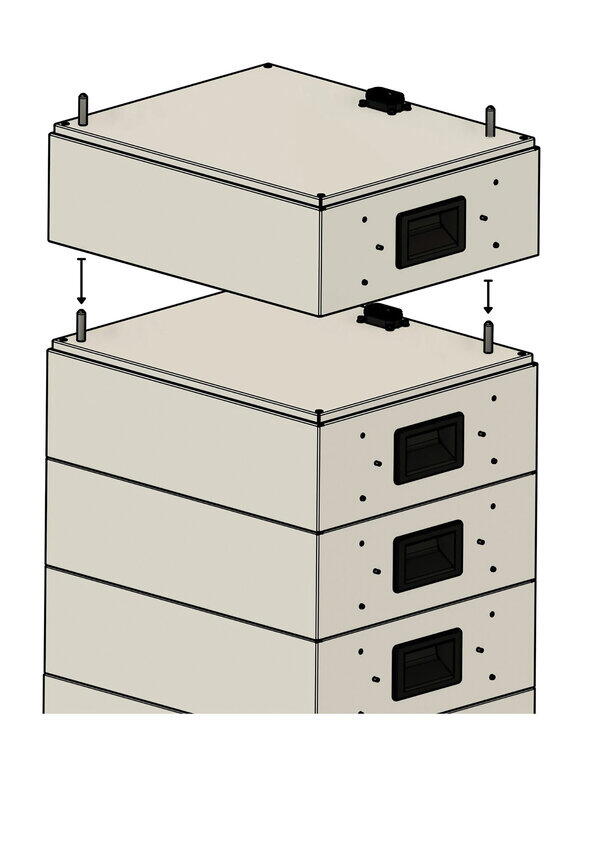

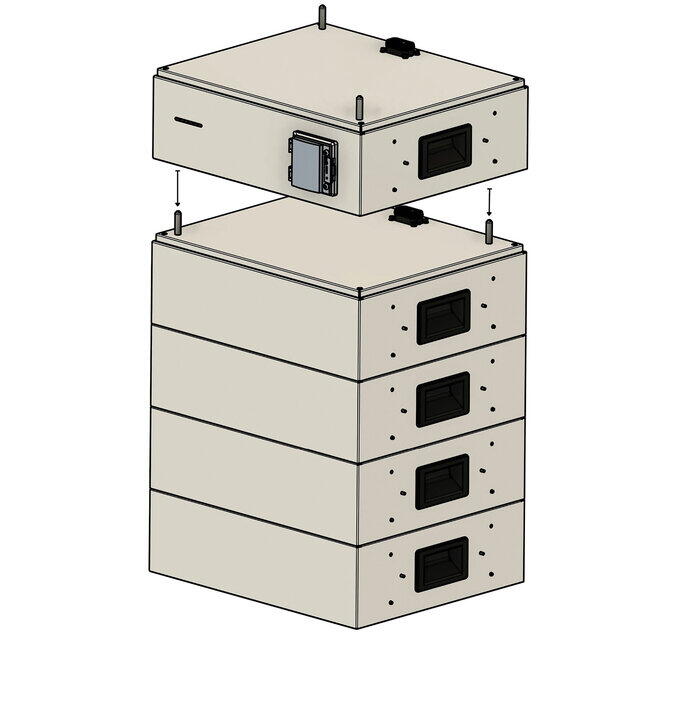

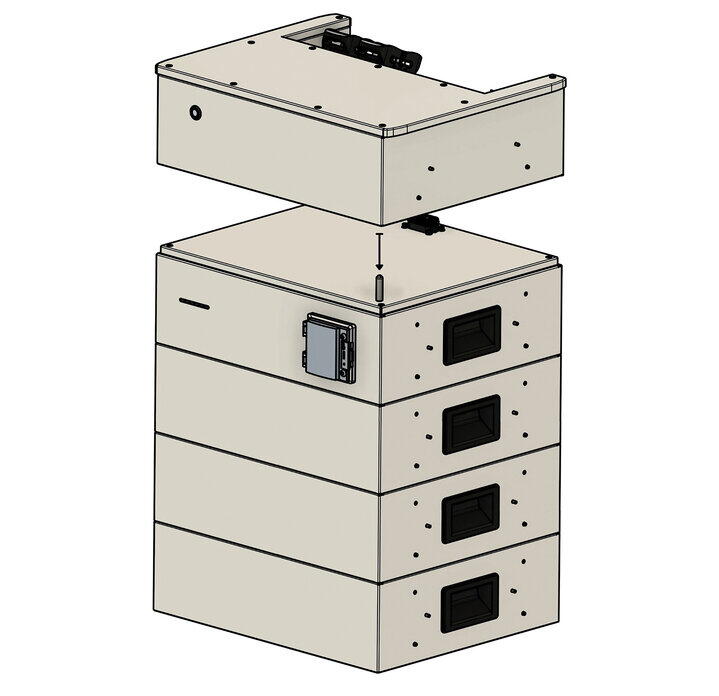

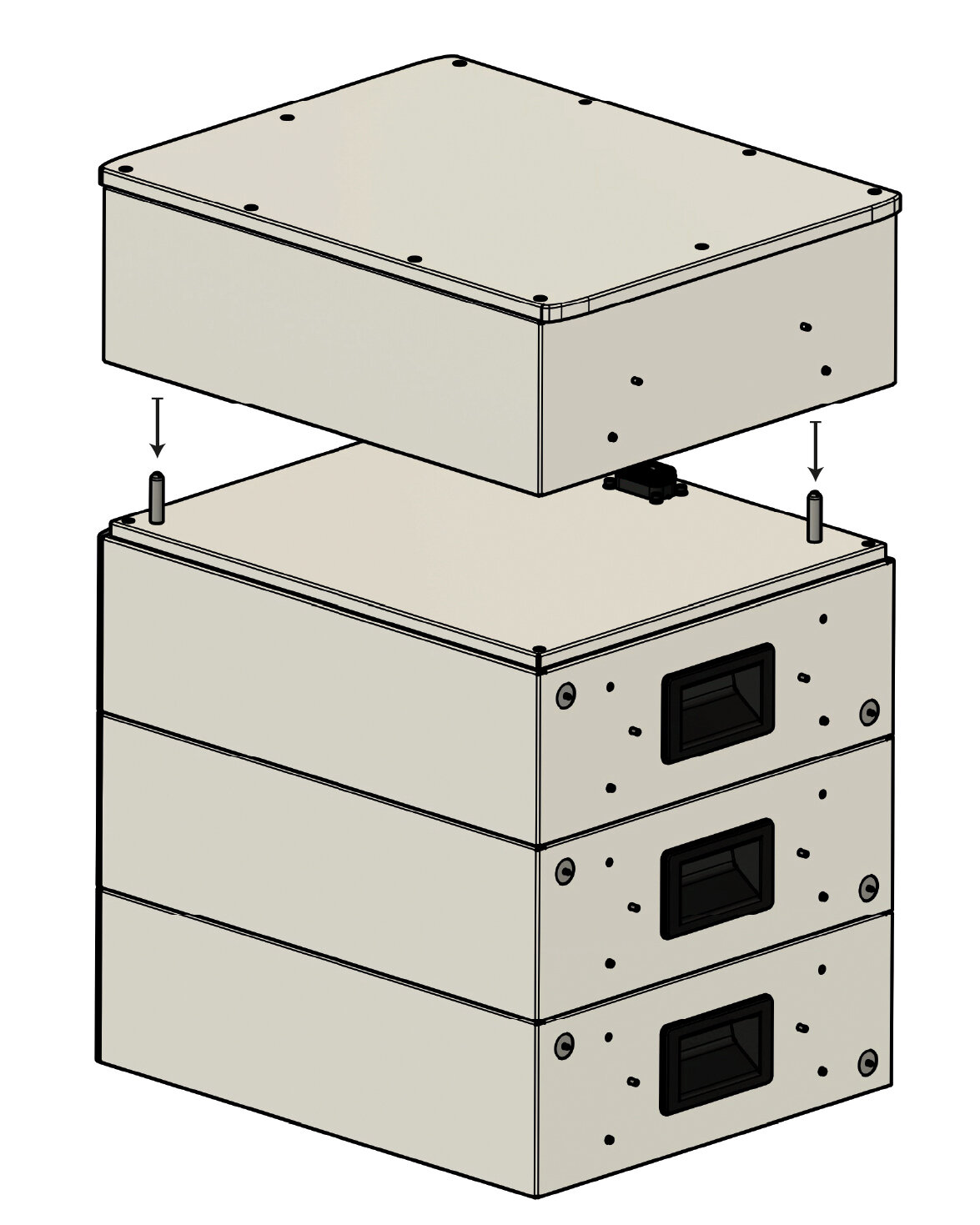

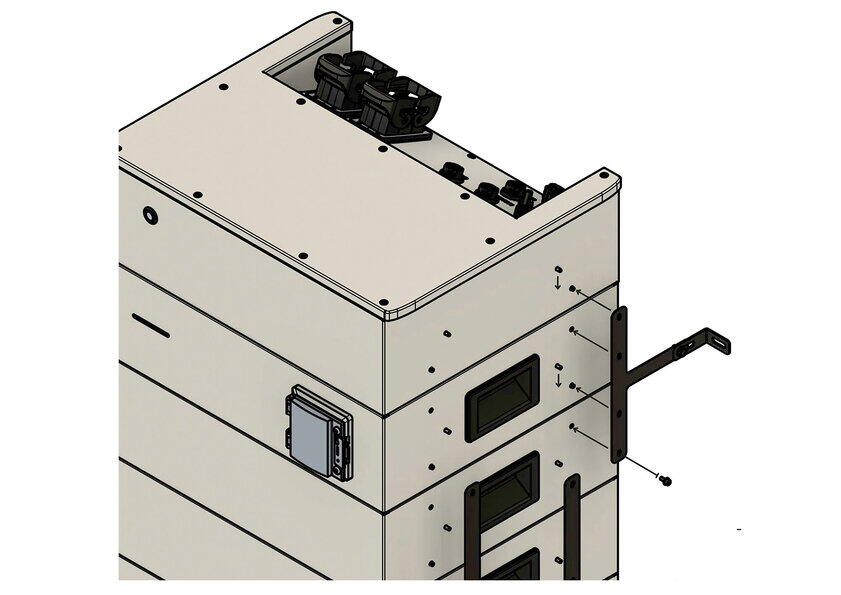

6.2.4. Assembly of battery towers with FENECON Commercial 92 EMS box and FENECON Commercial 92 Extension box

Proceed as follows to set up a battery tower:

|

|

|

|

|

|

|

A maximum of 15 battery modules can be stacked on one base. |

|

|

|

Electric shock

|

|

|

|

|

|

|

|

|

|

|

|

|

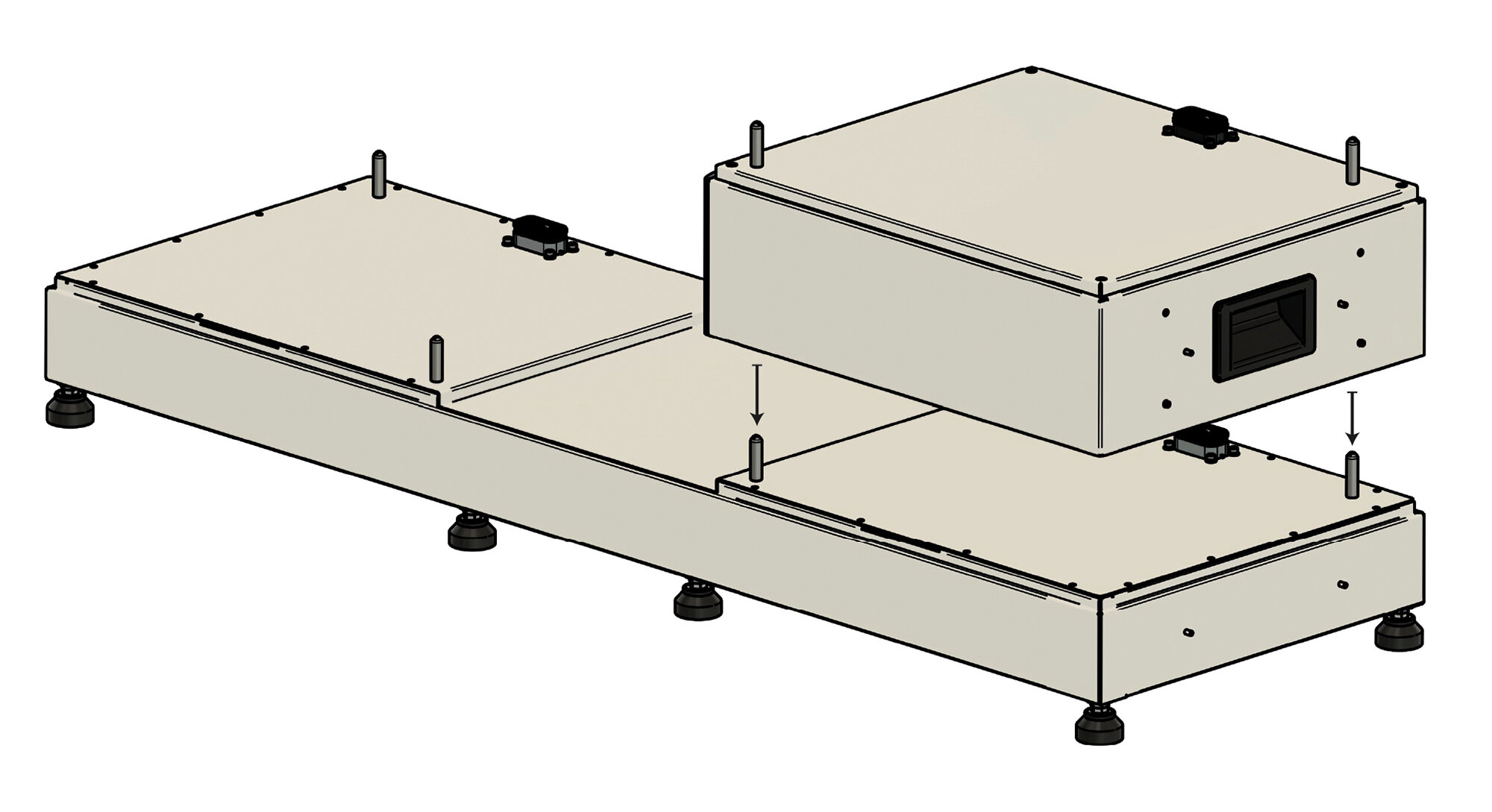

6.3. Installation — Battery tower on split base

|

The split base can only be used with battery modules with item number FEH021. |

|

The split base is used for a larger footprint installation of a battery tower, which reduces its height and enables installation in rooms with low ceilings. |

Proceed as follows to set up a battery tower with a split base:

|

|

|

|

|

|

|

|

|

|

Electric shock

|

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

6.4. Electrical installation

6.4.1. Earthing the inverter and battery towers

|

|

|

|

|

The cross-section of the earthing must be at least 10 mm2. + → The inverter and the battery towers must be earthed individually to the equipotential bonding. |

6.4.2. Connection and wiring of the KACO Inverter

| Item | Description |

|---|---|

1 |

Bi-directional meter from energy supplier |

2 |

Inverter fuse 3-pole. (see Inverter manual)*1 |

3 |

Fuse the load with RCD type A and suitable MCBs |

4 |

KACO inverter 92 kW |

5 |

Battery towers |

6 |

Fuse protection max. C6 or C10 1-pole |

7 |

Consumer load |

8 |

Power supply/grid connection |

9 |

Earth circuit connector |

*1 In addition, the currently valid national regulations and the specifications of the relevant grid operator must be observed. (If an RCD is required by the grid operator, an RCD type A with a tripping current of 300 mA is recommended; at 30 mA, unwanted shutdowns may occur.)

*2The currently valid national regulations, the specifications of the associated network operator and the manufacturer’s specifications must be observed.

|

The manufacturer’s manual supplied with the inverter must be used for the AC connection of the inverter. |

6.4.3. Connection and wiring of the 3-phase sensor without current transformer

(KDK 2PU CT)

| Item | Description |

|---|---|

1 |

Bi-directional meter from energy supplier |

2 |

Split-core CT (directly behind grid operator meter, not included in standard scope of delivery) |

3 |

Energy meter |

4 |

Fuse for the energy meter (recommended) B6 3-pole |

5 |

Grid |

*1 In addition, the currently valid national regulations and the specifications of the relevant grid operator must be observed. (If an RCD is required by the grid operator, an RCD type A with a tripping current of 300 mA is recommended; at 30 mA, unwanted shutdowns may occur.)

|

Please note: To install the meter, use the installation and configuration instructions — FEMS package 3-phase sensor without current transformer (KDK 2PU CT): https://docs.fenecon.de/de/fems/fems-app/installationsanleitungen/KDK_2PU_CT_Installationsanleitung.html |

The Modbus communication available with the 2PU CT takes place via a serial RS485 interface (2 or 3 wire), which enables the device to be operated from FEMS. In the standard configuration, 64 devices can be connected to a PC or a controller over 1000 meters with one RS485 interface.

The connections for Modbus communication are located above the meter, in the front row of terminals.

-

COM RS-485 connection from the FEMS direction

-

Data conductor Positive (+) (A conductor)

-

Data conductor Negative (-) (B conductor)

-

Minus (-) contact

-

Plus (+) Contact

|

|

|

|

|

|

|

|

|

|

6.4.4. DC cable from the battery towers to the parallel switch box

|

|

|

|

|

The DC plugs used on the battery side are not compatible with standard MC4 plugs. |

6.4.5. Communication between inverter and EMS box

|

To seal the network connection, insert the enclosed 10 m network cable into the plug and screw it in place. |

|

Make sure that the network connector protrudes approx. 3 mm beyond the bayonet catch at the front. |

|

Connect the network cable to the INTERNAL port of the EMS box. |

|

Put the other end of the network cable through the screw connection of the inverter and connect it to the network port (4 — Ethernet for network connection DHCP). |

6.4.6. Communication between the batteries

|

|

6.4.7. Communication with the customer network

|

|

|

If the battery tower is installed indoors, this step can be skipped. And the network cable can be plugged in directly. |

|

|

|

|

|

The system does offer WiFi functionality. |

6.4.8. AC connection of the FENECON EMS box

An external 230-V-power-supply is required to supply the FENECON EMS box.

The purpose of this is to avoid straining the empty battery with additional consumer loads. This can occur particularly in winter when there is no sunshine or when there is snow on the PV system.

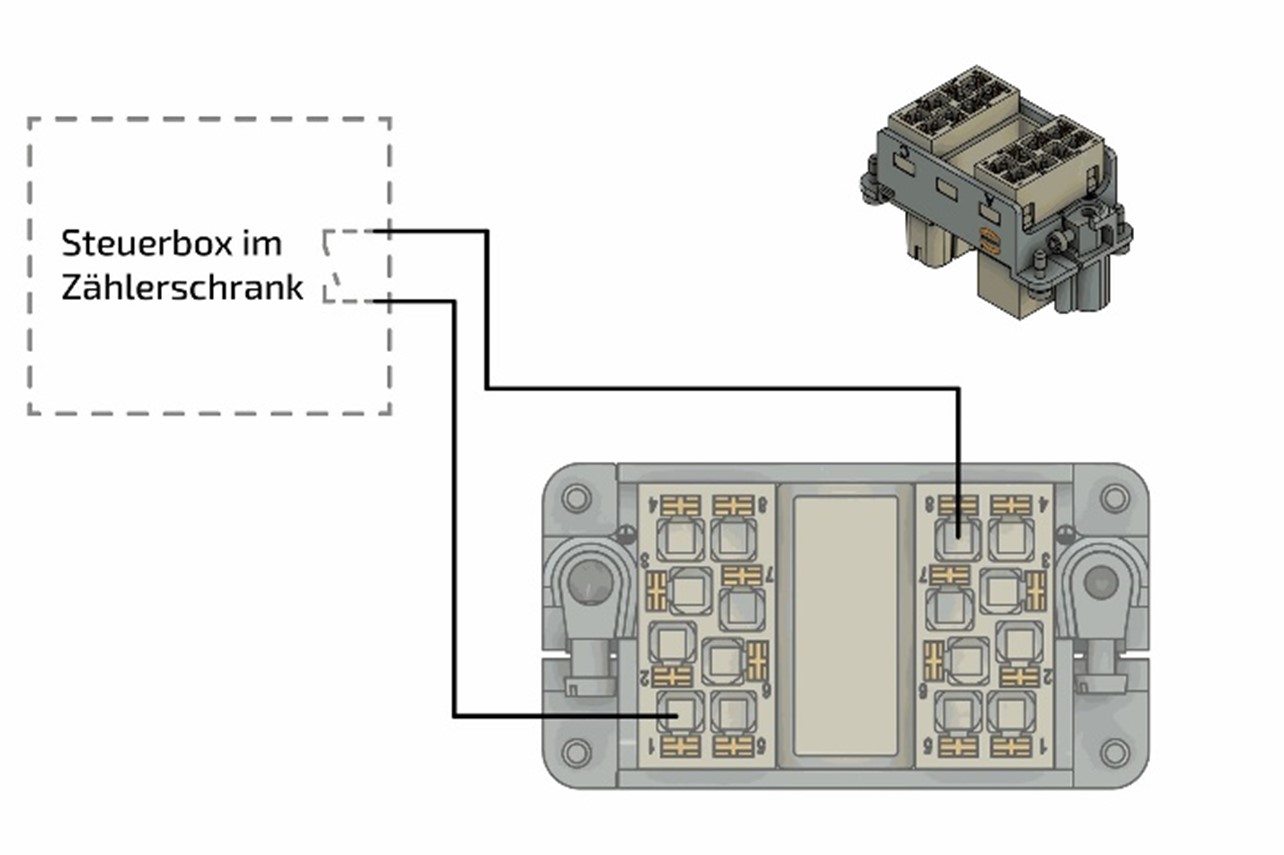

|

|

|

|

|

|

|

|

|

|

7. Initial commissioning

7.1. Checking the installation, connections and cabling

Check the system as follows before initial commissioning:

-

All components (distances, environment, mounting) are installed correctly.

-

All internal wiring is complete and properly connected.

-

All external supply lines (power supply, communication cable) are properly connected.

-

All connected loads are matched to the system and the necessary settings have been made.

-

All necessary tests of the system were carried out in accordance with the standards.

|

Commissioning must only be carried out by trained specialist personnel. |

|

|

This is indicated in the installation and service instructions:

|

7.1.1. Switch on

|

|

|

|

| If commissioning has not yet been completed, the battery will not start. |

|

The system is restarted by pressing the push-button on the front of the EMS box. The restart can take up to three minutes. |

|

If the system has not yet been configured, the battery goes into error mode or switches off. The inverter only starts after configuration and only then synchronizes to the grid. |

7.1.2. Switching off the system

|

Rack out the battery towers (front battery tower). |

7.2. Configuration via commissioning wizard

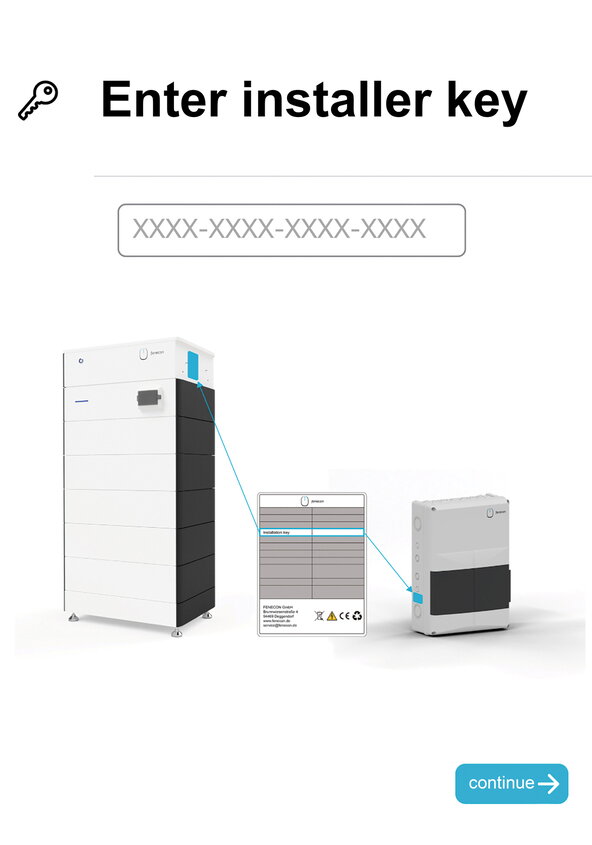

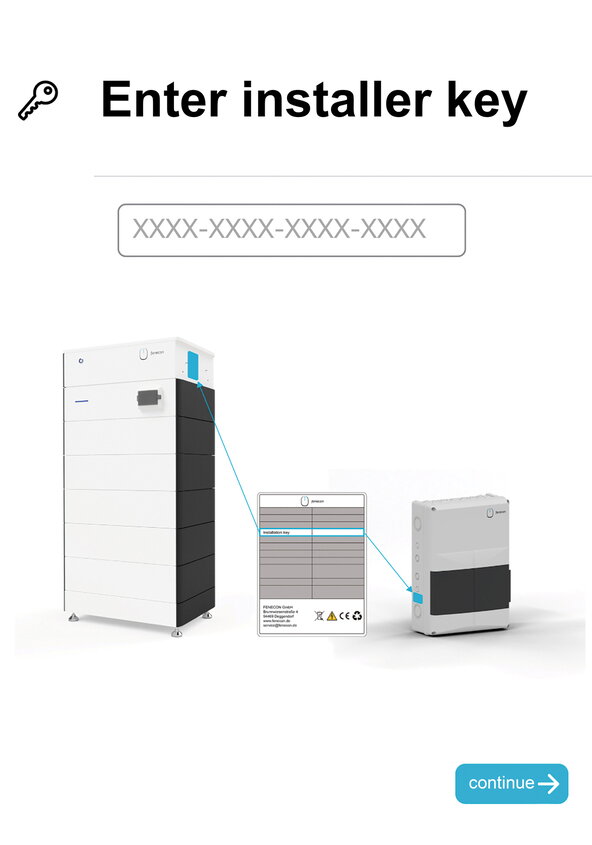

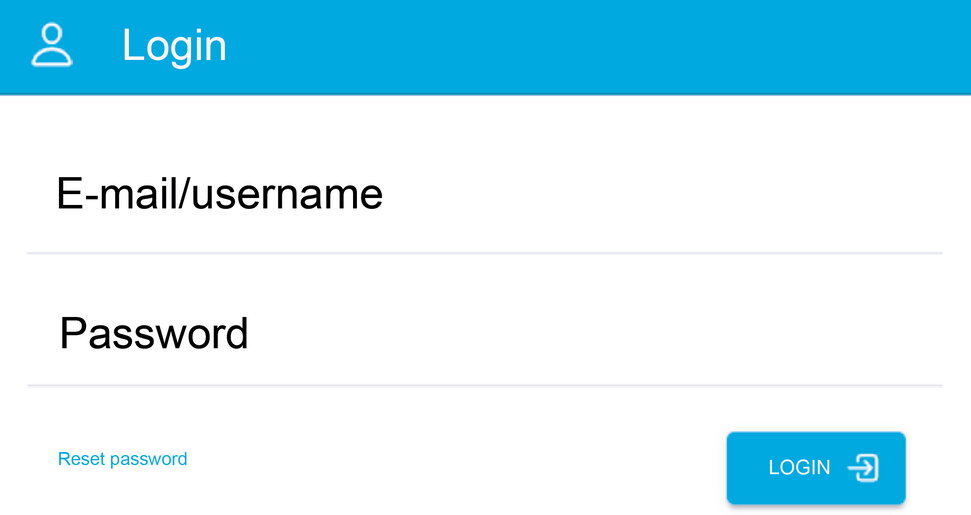

Open the FENECON homepage and click on the login for FEMS Online Monitoring "FEMS login" in the top right-hand corner. Alternatively, you can use the following QR code or link to access the page.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

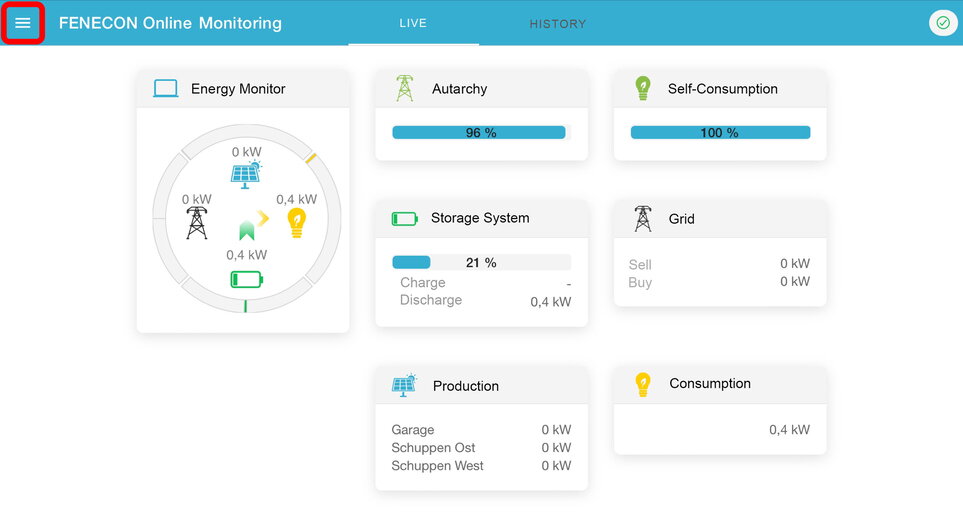

8. FEMS Online Monitoring

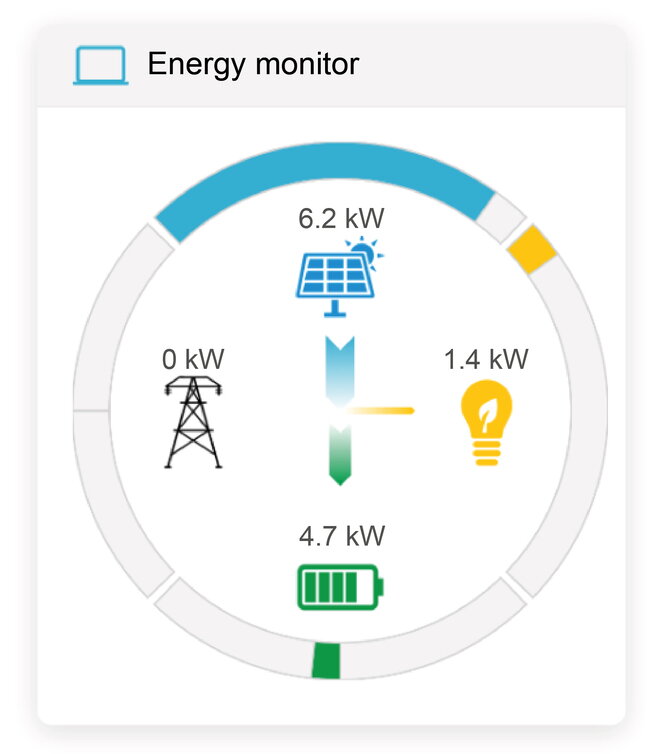

The FEMS Online Monitoring is used to visualize all energy flows in your system. The energy monitor shows live data on grid withdrawal or feed-in, PV production, charging/discharging of the battery storage system and electricity consumption. Other widgets display the percentage of self-sufficiency and self-consumption. In addition, the individual widgets offer a detailed view, which can also be used to view the performance values with phase accuracy.

In addition to the pure information display, all additionally purchased FEMS extensions, such as for integrating a heat pump, Heating element, Combined Heat and Power plant (CHP), are also listed in Online Monitoring. Their functionality can be controlled via the corresponding widget.

In addition to the live view, the history offers the option of selecting user-defined time periods for Online Monitoring. The status of the entire system and the individual components can be monitored at any time using the info icon.

8.1. Access data

Access to FEMS Online Monitoring is separated according to end customer and installer.

8.1.1. Access for the end customer

Access for the end customer is generated automatically after commissioning is complete and sent to the end customer by email.

The terms and conditions still need to be confirmed here, then the monitoring is available without restrictions.

If additional users want to access the system, they must create their own user account. This is done as described in the section Configuration via commissioning wizard, but here "USER" must be selected in the header.

After successfully creating an additional user account, all we need is an email to service@fenecon.de with the email address used and the FEMS number concerned, we will create the link and other users can use the Online Monitoring of a system.

8.1.2. Access for the installer

The installer account can be created as described in the section Configuration via commissioning wizard on the FENECON homepage. Access is required for successful commissioning. <<<

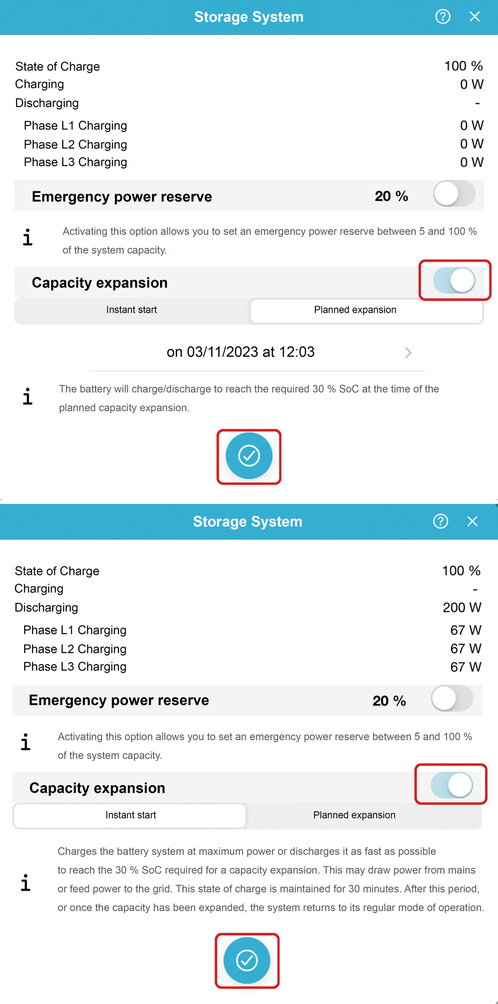

8.2. Capacity expansion of the system

by one or more battery towers

The capacity of the system can be subsequently expanded by one or more battery towers with the same capacity. There is no time limit here.

The maximum expansion of the FENECON Commercial 92 system comprises of up to 5 battery towers, each with 15 battery modules and 210 kWh.

The full capacity is not achieved with new battery modules, as the new modules become similar to the old modules.

Proceed as follows before the extension:

|

|

|

|

|

|

|

|

|

9. FEMS extensions

For the following FEMS extensions, the integrated relays can be used directly on the (first) battery tower.

Various pins on the Harting plugs are provided for this purpose.

-

Harting plug 10-pin: 3 x free relay channels (max.: 230 V; 10 A)

-

Harting plug 16-pin: 2 x control contacts (max.: 24 V; 1 A)

-

3 x digital inputs

-

1 x analog output (0-10 V)

-

It may not be possible to connect and operate all apps at the same time.

For more information on the following apps, please visit our homepage.

|

If the integrated relays are not sufficient, an external 8-channel relay board can be connected via Ethernet. |

|

The pin assignment of the Harting plug (10-pin) is shown in detail below. |

| Item | Description |

|---|---|

1 |

230 V supply for internal components |

2 |

Relay 1 (230 V; 10 A) |

3 |

Relay 2 (230 V; 10 A) |

4 |

Relay 3 (230 V; 10 A) |

5 |

Neutral conductor connection (required for integrated meter) |

6 |

PE connection |

|

The pin assignment of the Harting plug (16-pin) is shown in detail below. |

| Item | Description |

|---|---|

1 |

RS485 connection — Mains meter |

2 |

RS485 connection — External devices |

3 |

Analog output (0-10 V) |

4 |

12 V DC (12V; GND) |

5 |

3 x digital inputs |

6 |

Not assigned |

7 |

Relay 5 (24 V; 1 A) |

8 |

Relay 6 (24 V; 1 A) |

9 |

CPC connection |

9.1. Connection of a heat pump via "SG-Ready"

The integration of an "SG-Ready" (Smart-Grid-Ready) heat pump is an advanced form of sector coupling of electricity and heat — often also referred to as a "Power-to-Heat" application. The control system ensures that the heat pump slightly overheats the thermal storage unit at times when cheap (solar) electricity is available in order to save electrical energy at times when there is no cheap surplus electricity.

|

1. The internal relay contacts 5 and 6 can be connected via pins 5/6 and 7/8 on the Harting plug (16-pin — C). |

|

After installing the components, the app still needs to be installed. |

9.2. Connection of a Heating element with a maximum of 6 kW

The integration of an electric heating element is the simplest and cheapest form of sector coupling of electricity and heat — often also referred to as a "Power-to-Heat" application.

If the capacity of the electrical storage unit is at maximum, self-generated energy is fed into the public grid with low remuneration. In these cases, it often makes sense to use the surplus electricity for water heating (e.g. for hot water buffer tanks, pool heating, etc.). In this way, other energy sources (e.g. wood or oil) can be saved.

|

|

|

Care must be taken to ensure that three different phases are used. If only one phase is used, damage may occur. |

|

After installing the components, the app still needs to be installed. |

| Manual mode is only suitable for temporary operation. For permanent operation, the external relay control must be used. |

9.3. Control of a heating element greater than 6 kW (control via external relay)

The integration of an electric heating element is the simplest and cheapest form of sector coupling of electricity and heat — often also called a "power-to-heat" application.

If the capacity of the electrical storage unit is exhausted, self-generated energy must be fed into the public grid with low remuneration. In these cases, it often makes sense to use the surplus electricity for water heating (e.g. for hot water buffer tanks, pool heating, etc.). In this way, other energy sources (e.g. wood or oil) can be saved. The externally installed relays must suit the set output of the heating element installed.

|

|

|

|

|

|

|

After installing the components, the app still needs to be installed. |

9.4. Control of a CHP unit

The integration of a Combined Heat and Power plant (CHP) into electrical energy management is an advanced form of sector coupling of electricity and heat.

This enables the application of the CHP unit as an electrical generator that is independent of the time of day and weather conditions. The CHP unit is given a switch-on signal to produce electricity when the storage unit’s charge level is low. This is useful, for example, if the battery capacity is not sufficient to cover electricity consumption at night. This avoids the need of purchasing expensive electricity from the grid.

When the battery is charging, this signal is stopped again to prevent the CHP power from being fed into the grid unnecessarily.

|

1. The enable signal for starting the CHP can be connected to pins 5/6 via the Harting plug (16-pin — C). |

|

After installing the components, the app still needs to be installed. |

9.5. Additional AC meter

If other meters have been installed for monitoring other consumers or generators, these must be integrated into the circuit in accordance with the manufacturer’s instructions. +

The communicative integration is shown below using a 3-phase sensor without a current transformer as an example.

Only meters approved by FENECON can be integrated.

The first generation meter is always integrated with Modbus ID 6. All others in ascending order. The baud rate is 9600.

|

|

|

Example: SOCOMEC E24

|

|

Example: KDK 4PU

|

|

If several meters are to be installed, they can be connected in series for communication purposes. Here, the first meter can be bridged to the second, etc. The Modbus address must be set in ascending order. |

|

After installing the components, the app still needs to be installed. |

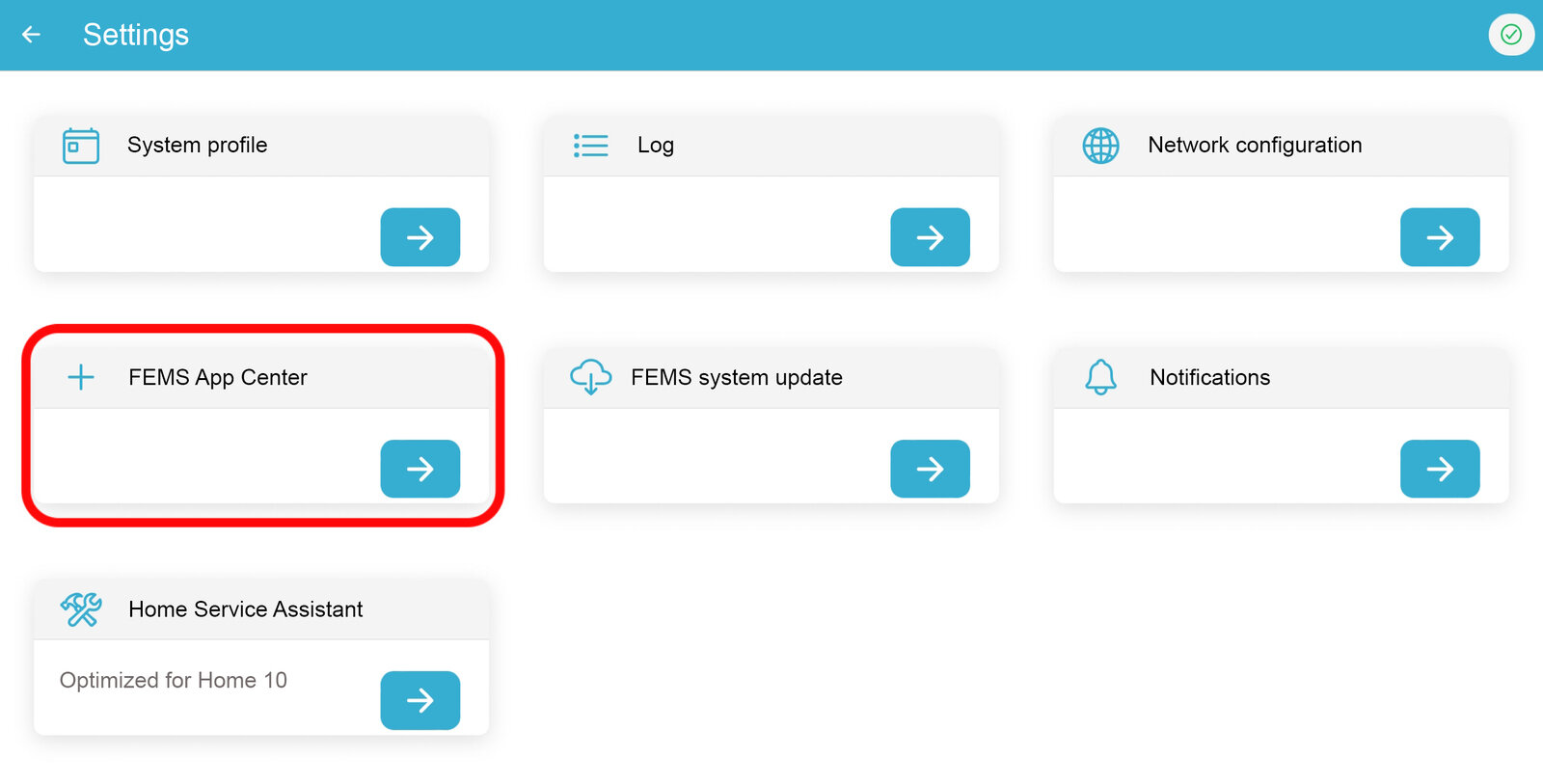

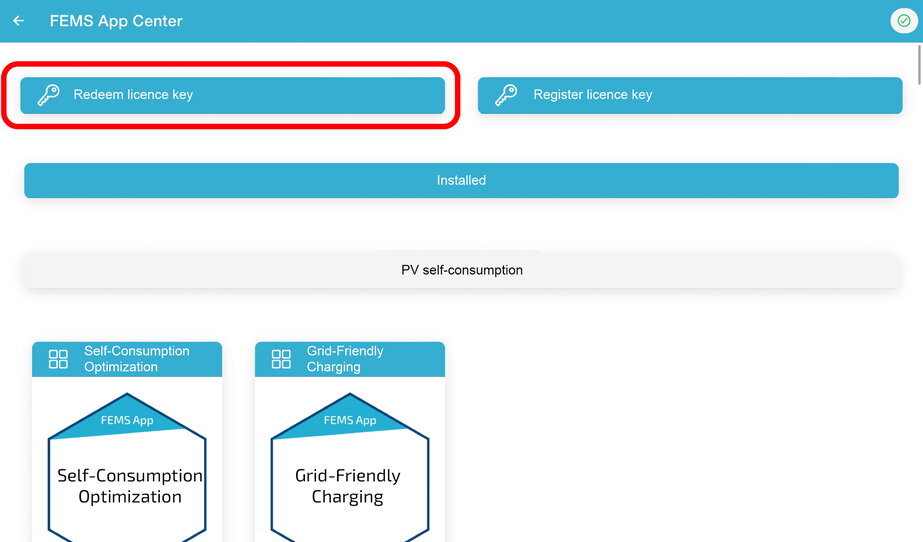

9.6. Activation of the app in the FEMS App Center

After installing the hardware FEMS extension, it still needs to be activated in the App Center. To do this, proceed as follows:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10. External control of the inverter

There are various ways to override the inverter from external devices.

10.1. § 14a of the Energy Industry Act (EnWG)

The Inverter can be limited to a maximum reference power of 4.2 kW. The digital input of the EMS must be assigned for this.

|

|

11. Troubleshooting

11.1. Errors in Online Monitoring

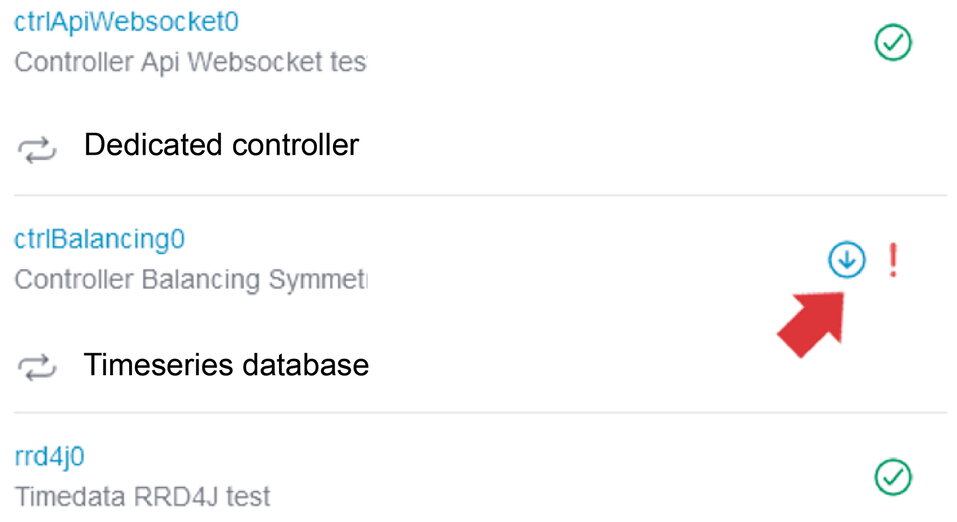

The system status can be checked after logging in at the top right using the color of the symbol. A green tick indicates that everything is OK, an orange exclamation mark indicates a warning (Warning) and a red exclamation mark indicates an error (Fault).

11.1.1. Fault display

System status: Everything is fine |

|

System status: Warning |

|

System status: Error (Fault) |

11.1.2. Troubleshooting

|

You can get a detailed overview of an existing warning or error by clicking on the exclamation mark in the top right-hand corner. |

|

The scroll bar can be used to examine the origin of the warning or error in more detail. |

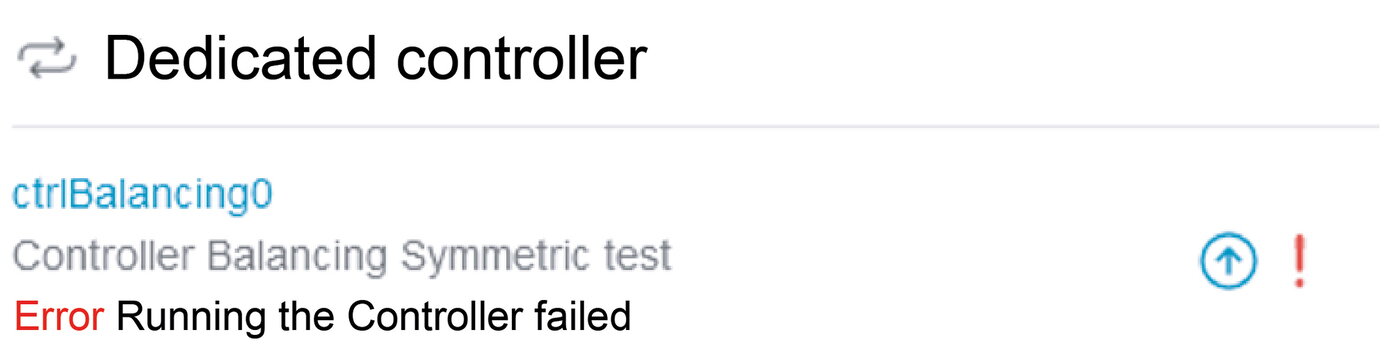

|

Clicking on the icon (down arrow) displays a more detailed error description depending on the error. |

In the example above, an incorrect reference for the network counter was intentionally entered for test purposes, which is why the controller fails to run.

|

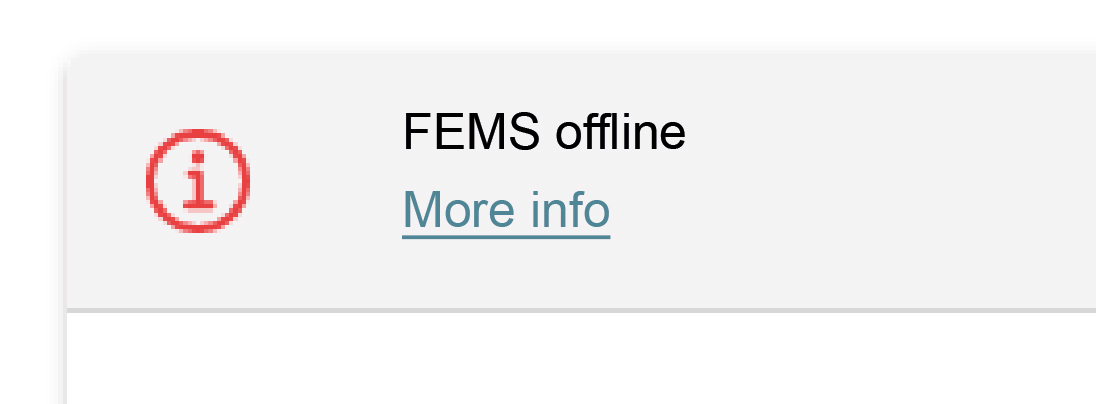

Under certain circumstances, it may happen that the FEMS is not accessible and the error message opposite appears. |

If the FEMS is offline, follow the steps displayed below the message.

11.2. Battery tower

11.2.1. Fault display

Faults are displayed on the BMS box via a red LED.

The various errors are indicated by LED codes.

| Memory status | Memory info | LEDs | |||||

|---|---|---|---|---|---|---|---|

blue/red |

1 |

2 |

3 |

4 |

|||

Bootloader |

|||||||

Start |

Master/Slave |

||||||

Parallel switch box |

|||||||

Extension-Box |

|||||||

Check mode |

Individual or parallel connection |

||||||

SoC display |

|||||||

Charging |

0 % bis 25.0 % SoC |

||||||

25.1 % bis 50.0 % SoC |

|||||||

50.1 % bis 75.0 % SoC |

|||||||

75.1 % bis 99.9 % SoC |

|||||||

100 % SoC |

|||||||

Discharging and standby |

100%-75.1% |

||||||

75.0%-50.1% |

|||||||

50.0%-25.1% |

|||||||

25.0%-0% |

|||||||

Error |

Overvoltage |

||||||

Undervoltage |

|||||||

Overtemperature |

|||||||

Undertemperature |

|||||||

Overcurrent |

|||||||

SoH too low |

|||||||

Int. comm. |

|||||||

Ext. comm. |

|||||||

Parallel address error |

|||||||

Module address error |

|||||||

BMS box fuse |

|||||||

Module fuse |

|||||||

Contact error |

|||||||

Insulation error |

|||||||

BMS error |

|||||||

Blue, permanently on |

|

Blue, blinking |

|

Blue, flashing quickly |

|

Red, permanently on |

11.2.2. Troubleshooting

If faults cannot be rectified or in the event of faults that are not included in the fault list, the FENECON Service must be contacted. See section Service.

11.3. Fault list

| Component | Disturbance | Measure |

|---|---|---|

Battery module |

The battery module has become wet |

Do not touch |

Battery module |

The battery module is damaged |

A damaged battery module is dangerous and must be handled with the utmost care. |

11.4. Service

The FENECON service must be contacted in the event of system faults:

Phone: +49 (0) 9903 6280-0

E-mail: service@fenecon.de

Our service hours:

Mon. to Thurs. 08:00 to 12:00 h | 13:00 to 17:00 h

Fri. 08:00 to 12:00 h | 13:00 to 15:00 h

12. Technical maintenance

12.1. Tests and inspections

|

When carrying out inspection work, ensure that the product is in a safe condition. Improperly performed inspections can have serious consequences for people, the environment and the product itself. |

|

Inspection work must only be carried out by trained and qualified specialists. |

|

The maintenance instructions of the component manufacturer must be observed for all individual components. |

Check the product and the cables regularly for visible external damage. If components are defective, contact the FENECON Service. Repairs must only be carried out by a qualified electrician.

12.2. Cleaning

Cleaning agents: The use of cleaning agents can damage the electrical energy storage unit and its parts.

It is recommended that the electrical energy storage unit and all its parts are only cleaned with a cloth moistened with clean water.

|

The entire product must be cleaned regularly. Only suitable cleaning agents may be used for this purpose. |

12.3. Maintenance work

No regular maintenance work needs to be carried out on the system, but check the status of your electrical energy storage system regularly.

|

The capacity guarantee applies if the capacity of a battery module falls below 70 % of the amount of energy shown as usable capacity before reaching 6,000 full cycles on the battery output side (DC) if a 2.2 kWh battery module has a capacity of less than 1.54 kWh. For the FENECON Home 6, 10 & 15 and FENECON Home 20 & 30 models, the amount of energy falls below 70 % of the usable capacity if a 2.8 kWh battery module has a capacity of less than 1.96 kWh. |

13. Note for fire departments regarding FENECON Home & Commercial systems

The FENECON Home and Commercial systems operate in the low-voltage range, which means that they are operated with voltages of less than 1,500 volts direct current (DC) and less than 1,000 volts alternating current (AC).

It may be useful to install an additional switch that disconnects the building from the emergency power supply. This makes it easier for the fire department to act safely and quickly in an emergency.

For a precise procedure for emergency services, it is recommended to ask the relevant fire department schools and request the corresponding information sheets and pocket cards for battery storage systems.

14. Flood safety measures FENECON Home & Commercial

First steps after the water has receded

Even if your battery storage system looks undamaged on the outside:

-

Do not put the system back into operation yourself.

-

Ventilate the room well before entering (open windows from the outside if possible).

-

Avoid sparks (no smoking, no lighters).

Why a review is important:

Even though LFP batteries are very safe, water or moisture can:

-

Cause short circuits in the electronics.

-

Trigger corrosion of electrical connections.

-

Create isolation problems that only become apparent later.

These problems do not have to occur immediately, but can develop over weeks.

Commission a professional inspection

Contact:

-

Your installer or a qualified electrician with experience in battery storage.

-

FENECON, the manufacturer of your system.

-

Your insurance company — document the damage with photos.

The qualified specialist will check:

-

Whether water has entered the system.

-

Whether electronic components have been damaged.

-

Whether a recommissioning is safely possible or a replacement is necessary.

No recommissioning without approval

Battery storage systems that have come into contact with water must only be put back into operation after a professional inspection and express approval by a qualified specialist. This is for your Safety and is often also a prerequisite for your insurance cover.

When replacement is necessary

If your electrical energy storage needs to be replaced:

-

The defective system must be disposed of professionally by specialized companies.

-

Your installer will usually organize the removal and disposal.

-

Do not attempt to transport damaged batteries yourself

Interim storage until collection

If damaged battery modules cannot be collected immediately:

-

Store them well ventilated outdoors with sufficient clearance from flammable materials.

Storage in a-

Sand bed.

-

Fireproof container, not gas-tight, ventilated.

-

Water bath, e. g. metal tub, completely covered with water.

-

-

Keep children and pets away.

Status: October 2025

Source: According to Specifications of the Bundesverband Energiespeicher Systeme (BVES) e.V..

16. Transport

This section contains information on external and internal transportation of the product.

Transportation is the movement of the product by manual or technical means.

-

Only use suitable and tested lifting gear and hoists for transportation!

|

Risk due to lifted Loads! |

|

Check that the parts and outer packaging are in perfect condition. |

|

See for yourself that

|

Notes:

|

|

Legal regulations |

17. Dismantling and disposal

17.1. Prerequisites

-

The power supply to the Battery energy storage unit is interrupted and secured against being switched on again.

|

Sharp and pointed edges

|

17.2. Dismantling

-

The electrical Energy storage system must only be dismantled by authorized electricians.

-

Dismantling work must only be carried out when the system has been taken out of operation.

-

Before starting disassembly, all components to be removed must be secured against falling, tipping over or moving.

-

Dismantling work must only be carried out when the system is shut down and only by service personnel.

-

The dismantling instructions of the component manufacturers (see appendix, Other applicable documents) must be observed.

-

The current laws, regulations and standards must be observed when transporting the battery modules (e.g. Dangerous Goods Transportation Act - GGBefG).

17.3. Disposal

-

The FENECON electrical energy storage system must not be disposed of with normal household waste.

-

The FENECON electrical energy storage system is RoHS and REACH compliant.

-

Disposal of the product must comply with local regulations for disposal.

-

Avoid exposing the battery modules to high temperatures or direct sunlight.

-

Avoid exposing the battery modules to high humidity or corrosive atmospheres.

-

Dispose of the electrical energy storage system and the batteries it contains in an environmentally friendly manner.

-

Contact FENECON GmbH to dispose of the used batteries.

|